SIG Digital Solutions keep you connected

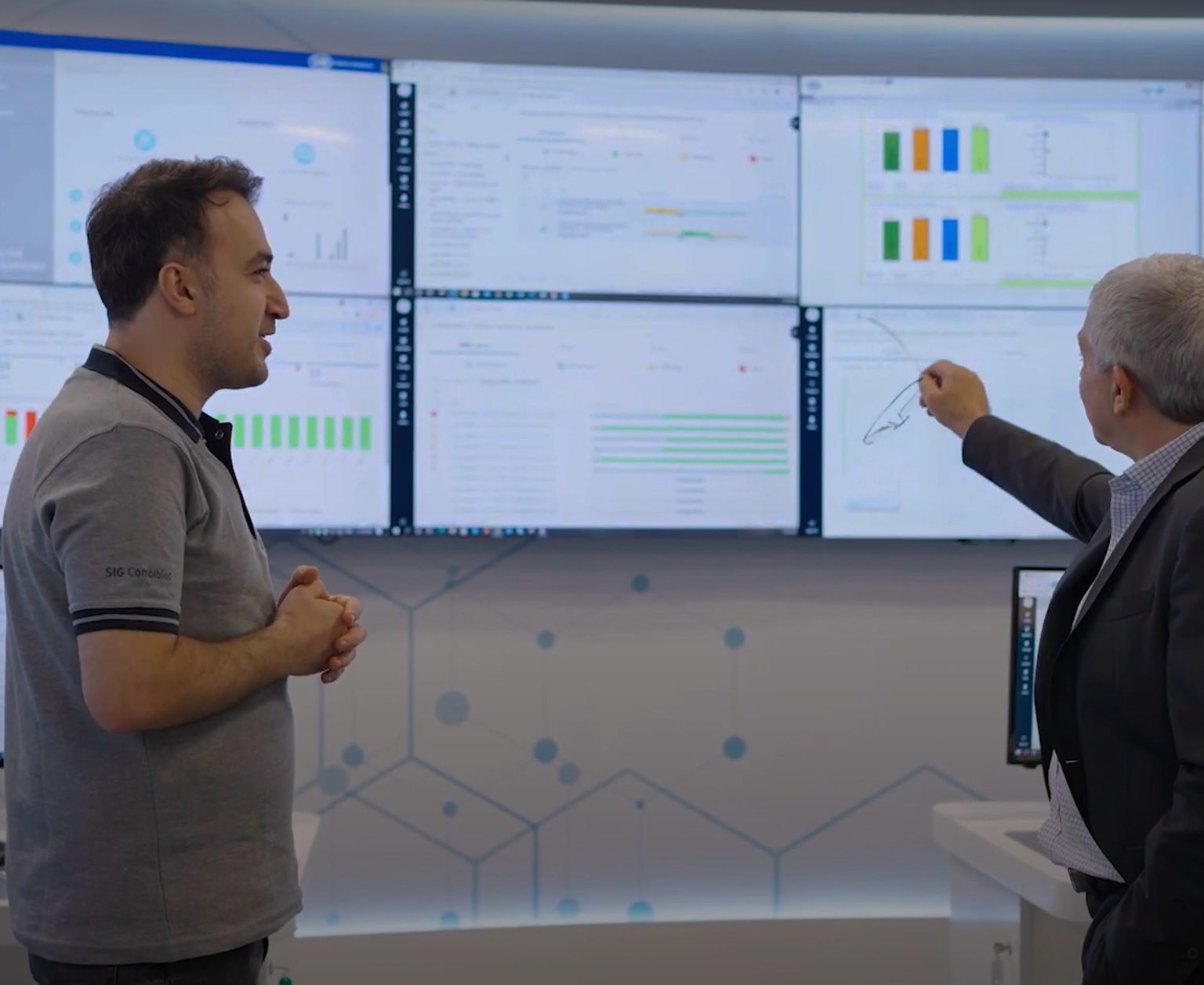

SIG Digital solutions have the power to make our factories smarter than ever. With access to more data and monitoring tools, manufacturers can increase productivity and sustainability with an eye toward growth and expansion.

At SIG, our suite of Digital Solutions are designed with efficiency in mind. Rather than just plugging in a piece of equipment and letting it go, the digital tools we've developed have delivered tangible results—we've helped manufacturers increase productivity by 8%, up line utilization by 30% and decrease costs through services that monitor equipment performance and uptime, save energy, and track produced packs in real-time.

Our Digital Solutions build smarter factories and provide digitally-enabled efficiency. We're optimizing plant operations for better and helping you address critical challenges in the food and beverage industry like managing asset productivity, increasing equipment availability and reducing downtimes, and improving quality and traceability.

Here's how we can help you maximize productivity, prevent unexpected downtimes, and ensure quality throughout your filling line through Digital Solutions:

SIG Line Monitoring

Gain real-time and historical visibility into the performance of your entire filling line to improve asset productivity.

SIG Asset Health Monitoring

Our Reliability Centers and state-of-the-art tools enable us to anticipate issues, recommend preventative measures, and offer solutions to optimize availability and reduce unplanned downtime.

SIG PAC.TRUST

Improves quality and traceability in operations.

SIG Connector

Your digital gateway to the SIG filling line.

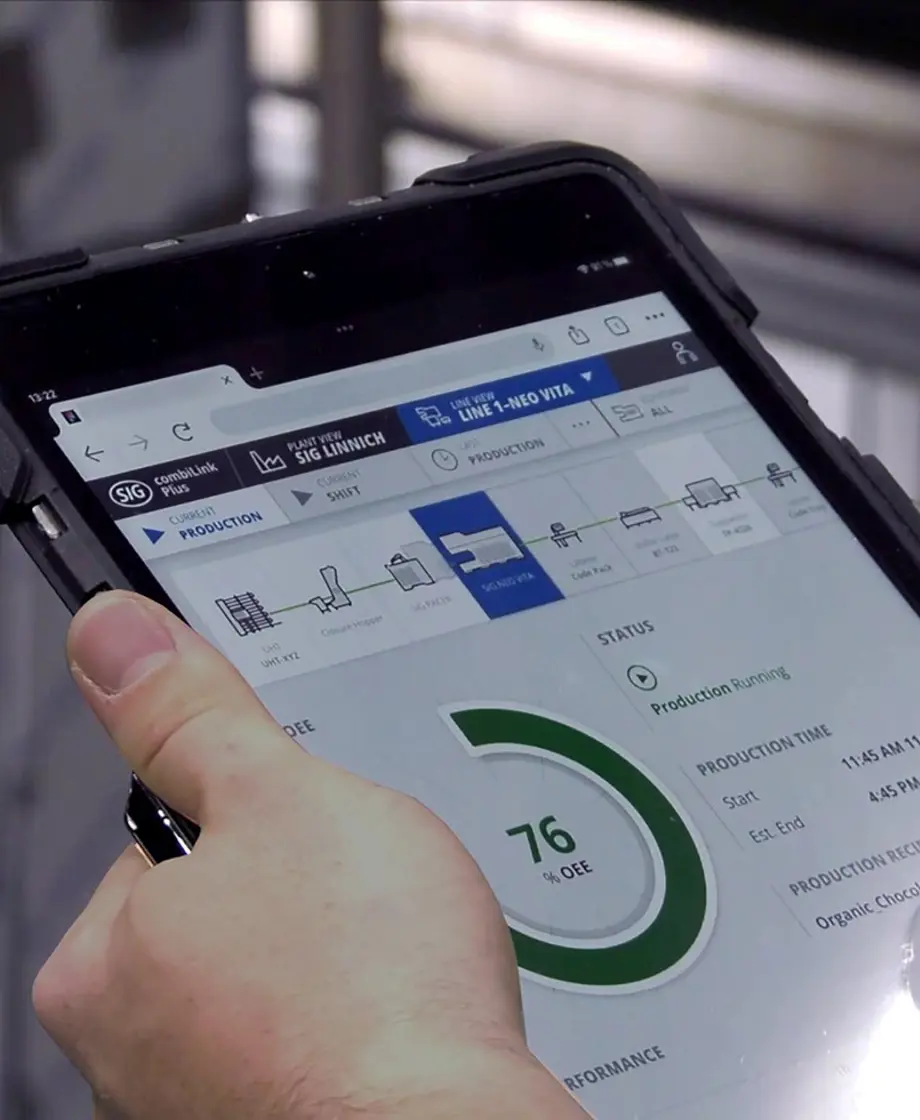

SIG Line Monitoring

Gain real-time insights and historical visibility into the performance of your entire filling line to improve asset productivity. SIG Line Monitoring service has an interface that visualizes data to help you better understand how well your filling machine is performing.

SIG Asset Health Monitoring

Our Reliability Centers and state-of-the-art tools enable us to anticipate issues, recommend preventative measures, and offer solutions to optimize availability and reduce unplanned downtimes.

SIG PAC.TRUST

Improves quality and traceability in operations. SIG PAC.TRUST is revolutionizing quality control processes, digitizing monitoring, and streamlining quality records.

SIG Connector

Your digital gateway to the SIG filling line. SIG Connector builds full connectivity in your plant, no matter what equipment, supplier, or PLC you have.

Please contact your SIG representative for more information.