Limiting global warming to 1.5°C is critical to prevent catastrophic climate change. To do this, the world needs to reach Net Zero: the point at which we achieve a balance between emissions produced and emissions taken from the atmosphere. Globally, we need to get there by 2050.

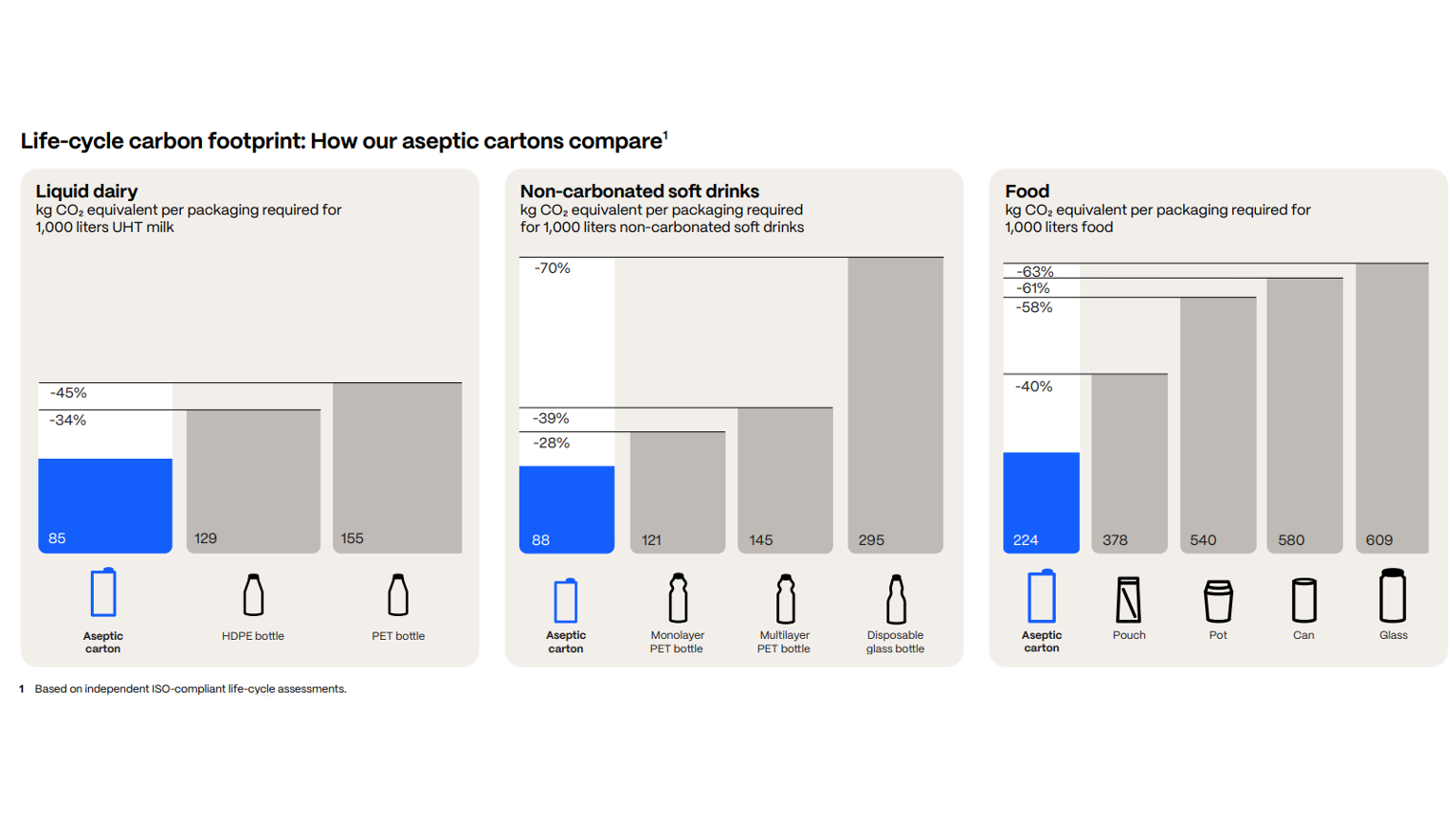

Everyone has a part to play in this, including us. Our packs already play a role in minimizing carbon emissions as they are designed and manufactured to have a far lower carbon footprint than other packaging formats, such as plastic and glass bottles or aluminum cans.

How do we do this?

Efficiency

Renewable Energy

Renewable Materials

We use high proportions of FSC™-certified (FSC™ trademark licence code: FSC™ C020428) low carbon renewable paperboard for all our cartons and ISCC PLUS-certified renewable polymers for some of our innovative SIG Terra solutions.

We are going further by committing to ambitious goals for our company and our products so that we increase our positive impact on our planet’s climate – also known as our “handprint”.

Our commitment: Net Zero

Our company goal: Reduce our carbon emissions to reach Net Zero by 2050.

We are committed to reducing our greenhouse gas (GHG) emissions to the levels demanded by science to keep global warming below 1.5°C. Our goal is to achieve Net Zero value chain GHG emissions by 2050 and our path to Net-Zero is approved by the Science Based Targets initiative (SBTi).

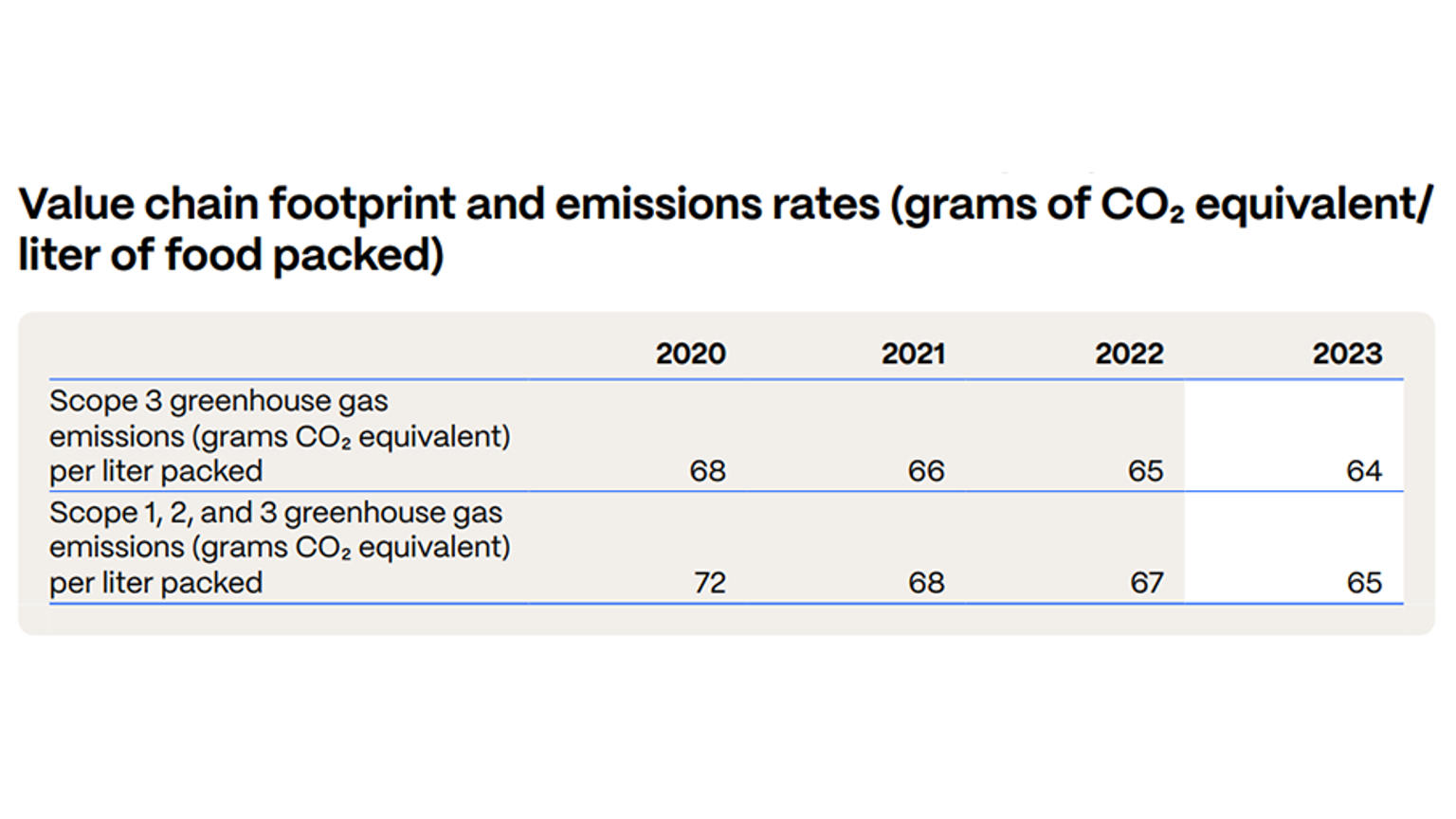

SIG’s near-term 2030 commitments (using 2020 as the baseline year) include:

- 42% absolute reduction of scope 1 and 2 GHG emissions

- 100% renewable electricity through 2030

- 51.6% reduction of scope 3 GHG emissions per liter packed

SIG’s long-term 2050 targets (using 2020 as the baseline year) include:

- 90% absolute reduction of scope 1 and 2 GHG emissions

- 97% reduction of scope 3 GHG emissions per liter packed

SIG was among the first 325 companies globally to have its target validated by the SBTi.

Our path to Net Zero

We have developed a series of workstreams to support progress on our path to Net Zero – supported by actions in other focus areas of our sustainability approach.

Together, these workstreams will help us meet our science-based targets and expand our positive impact by delivering GHG emissions reductions across the value chain and beyond:

Our operations

Further reducing our energy use through energy efficiency programs and new technologies.

Directly investing in renewable energy capacity through on-site solar and power purchase agreements.

Seeking viable alternatives to natural gas to cut emissions from heating (which we currently offset).

Our value chain

Reducing our use of carbon-intensive materials and encouraging suppliers to reduce their emissions.

Helping customers reduce their emissions by reducing energy requirements of our filling machines.

Increasing recycling rates of packs to avoid emissions from landfill and seeking lasting uses for recycled materials that store carbon in the long term.

Beyond our value chain

Continuing to offer the lowest carbon alternatives to other packaging types and increasing uptake of our lowest carbon solutions.

Mitigating food loss and waste through long-life packaging solutions and technical innovation.

Enabling carbon capture by restoring or creating additional thriving forests beyond what we need to make our cartons.

What have we achieved so far?

Cutting emissions

Since 2016, we have reduced Scope 1 and 2 emissions and our most significant Scope 3 emissions1 from our aseptic carton business by 20%.

1 Includes Scope 3 emissions from our supply chain, use of our filling machines and recycling or disposal of our cartons.

- We have maintained using 100% renewable electricity for production and offsetting non-renewable energy through Gold Standard CO₂ offsets for aseptic carton production since 2018. Since 2024, we have also been operating our newly acquired bag-in-box, spouted pouch, and chilled carton production facilities using 100% renewable electricity.

- We launched our next-generation filling machine for SIG aseptic cartons, SIG Neo, at the end of 2021. It is designed to cut energy use and offer a 25% lower carbon footprint for the filling and packaging process per pack compared with the previous generation.

Latest annual and CR report

Full detail of our path to net zero and our progress towards it can be found in our latest combined annual and corporate responsibility report.

Our commitment: lower carbon packs

Our product promise: Bring our customers the lowest carbon packaging solutions.

SIG packs are already designed and manufactured to have a carbon footprint that is far lower than other packaging formats. We are committed to pioneering even lower carbon packs.

To make the carbon footprint of our cartons even smaller, we are innovating to increase the proportion of low carbon paperboard we use and eliminate carbon intensive aluminum foil wherever possible. Where we do still use aluminum, we source it from responsible sources certified to Aluminium Stewardship Initiative (ASI) standards which require suppliers to follow a strict emissions reductions roadmap.

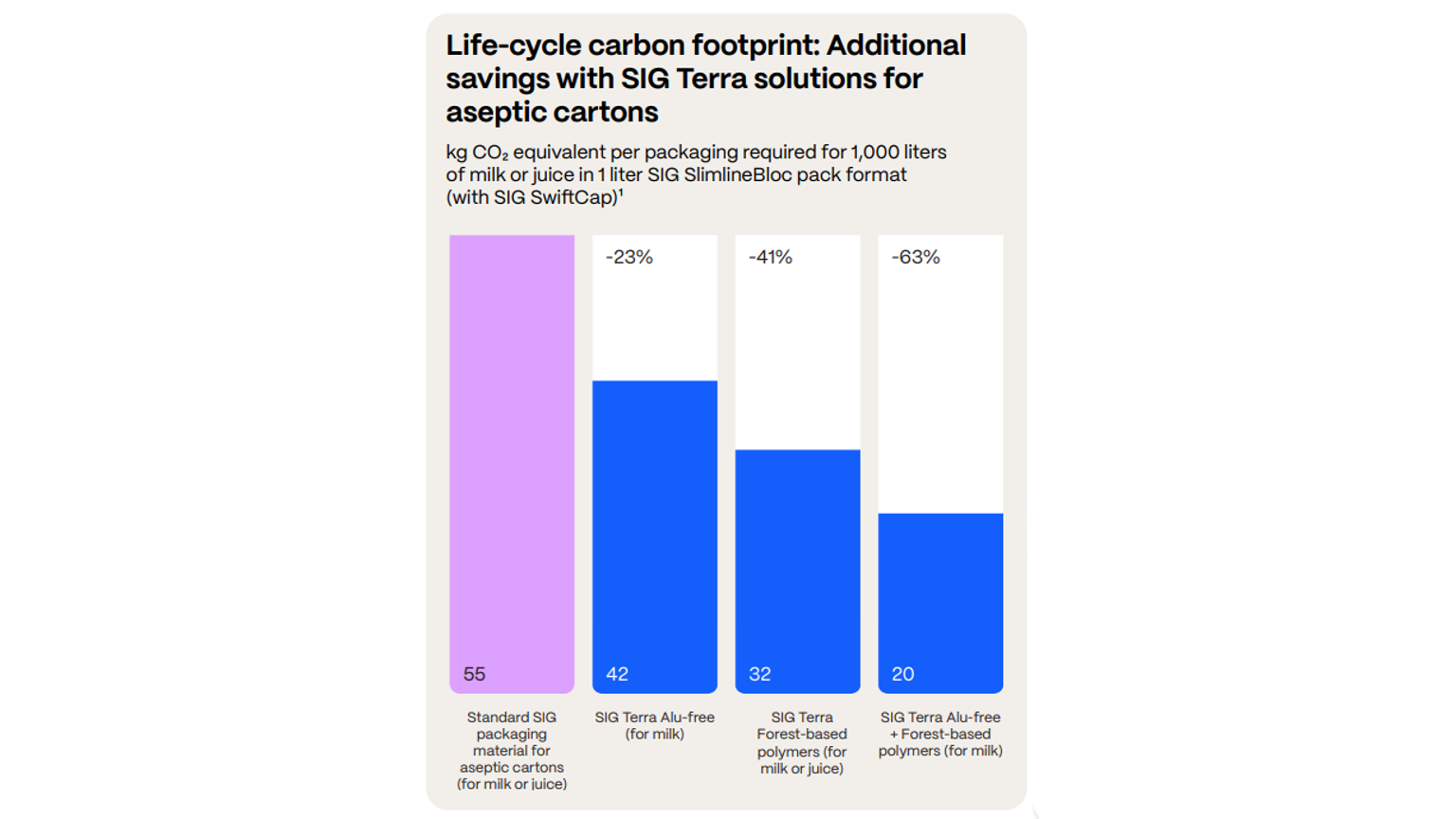

Our SIG Terra portfolio offers solutions with carbon footprints of 23% to 63% lower than that of our standard aseptic cartons.

Spouted pouch and bag in box solutions

Preliminary results* of an independent ISO-conformant life-cycle assessment conducted by the Institute for Energy and Environmental Research (IFEU) showed significantly lower carbon footprints:

-

Bag-in-box solutions for wine offer an 80% lower carbon footprint compared with glass bottles.

-

Recycle-ready spouted pouches for baby food offer an 11% reduction in carbon footprint compared with plastic tubs and a 59% reduction compared with glass jars.

We will keep going further to develop packaging that removes more carbon from the atmosphere than is emitted during its lifecycle. To do this, we will continue to minimize emissions from sourcing and production and helping to remove carbon from the atmosphere within and beyond our value chain.

*Results to be confirmed through an independent critical review process.