Spouted pouch filling technology

For over 60 years, SIG has engineered, built, and serviced a wide range of filling equipment for spouted pouch packaging. From lab-scale filling systems for trials and scaling up through high-speed aseptic filling solutions for high-volume production runs, we have what you need to provide a diverse range of products in environmentally-conscious packaging.

Flexibility is key for spouted pouch filling

Our spouted pouch filling equipment is widely known not just for its reliability, but also for its flexibility. SIG spouted pouch filling technology grows with you:

- Fill a variety of volumes, allowing you to reach retail and ecommerce consumers all with one piece of equipment

- Fill a variety of package formats with various fitments, allowing you to fill packages for at-home consumption through connections for dispensing equipment

- Lab-scale, pre-made spouted pouch filling equipment helps you get started in the pouch market, while our fully-automatic, aseptic fillers allow you to scale up to high-volume production runs

- Our filling solutions are compatible with products requiring ambient, ESL (ultra-clean), hot-fill, and aseptic processing

Two production methods

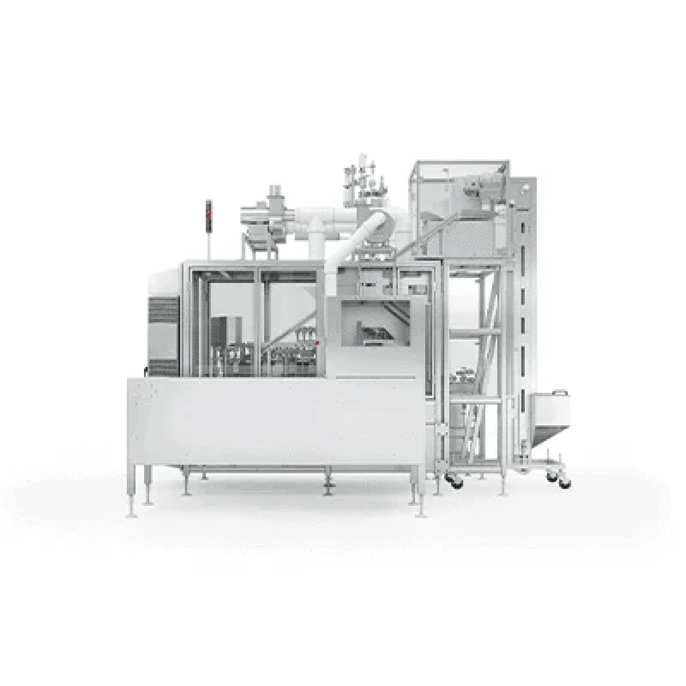

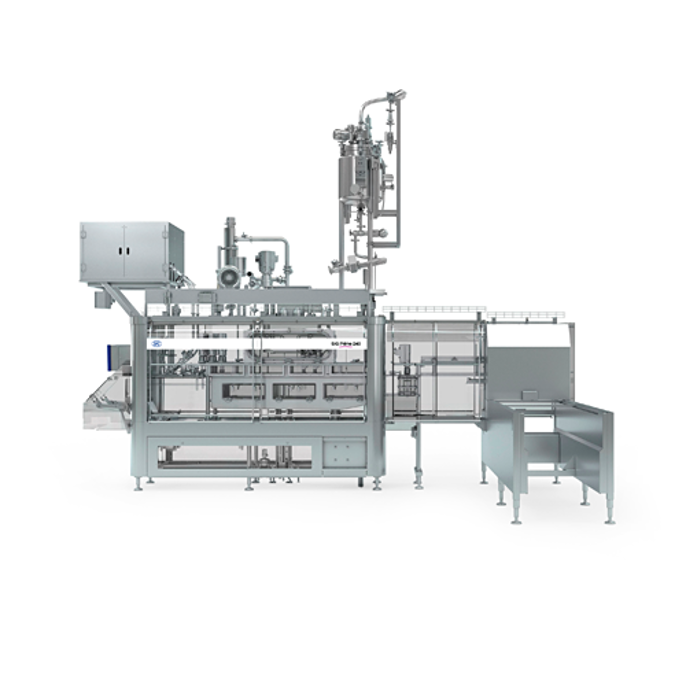

Pre-made

Keep it simple. Get your pouches from our production center and fill them with your product. You can focus on formulating, producing, and filling a winning product and leave the package manufacturing to us.

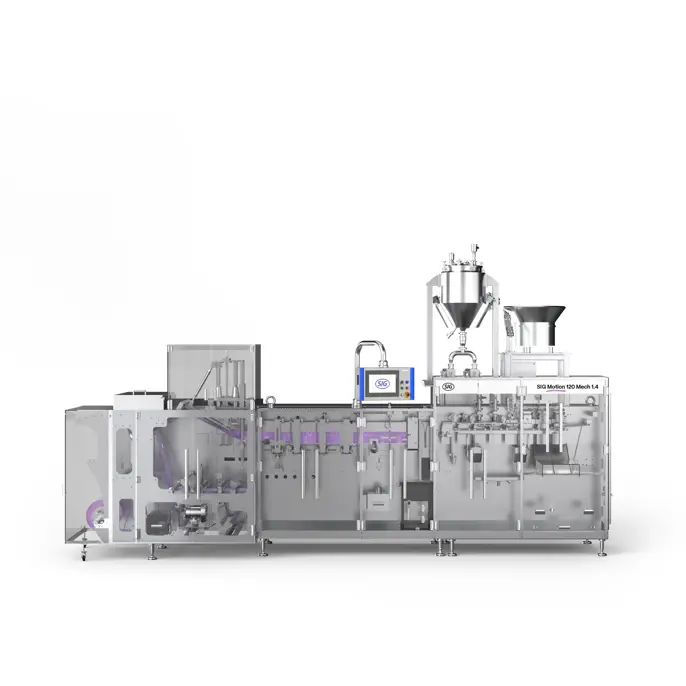

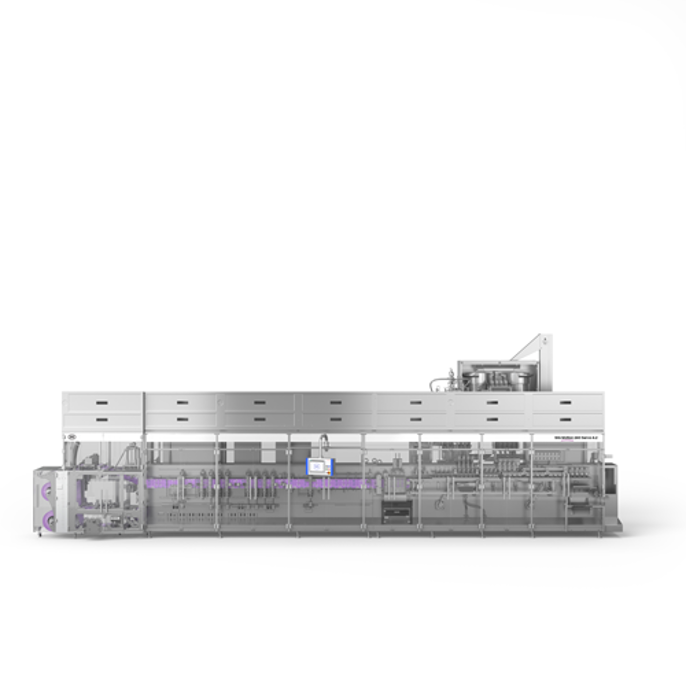

Horizontal form-fill-seal (HFFS)

Horizontal form-fill-seal machines (HFFS) form and seal pre-printed rollstock film into a pouch, fill product through the open pouch top, and seal fitments to the pouch all in a single machine. This method is perfect for large producers seeking the best TCO manufacturing option.

Our spouted pouch equipment

We deliver value for you by thinking end-to-end. Always.

Learn more about our solutions, from product innovation to packaging systems to smart production.