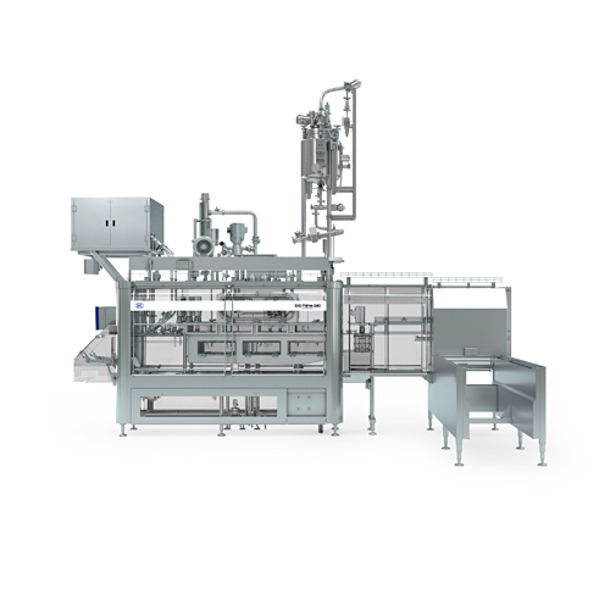

Redefined pouch filling efficiency

SIG Prime 240 features a simplified, compact linear design and unparalleled efficiency to fill pre-made spouted pouches. Equipped with a stainless steel, low-maintenance, self-lubricated chain, this filler moves the pouches through the stations with varying speeds as.

- Product is filled through the spout, in motion

- Motion filling improves output and speed

- Modular concept allows space for additional filling stations and flavors

Key features

Compact with quick changeovers, the SIG Prime 240 filler for pre-made spouted pouches enables tailored, multi-line systems that include multiple filling stations for one, two, or four flavors and filling options.

- Ideal for filling through the spout for liquid products

- Advantages of filling through the spout:

- Higher filling level in the pouch, resulting in reduced head space and less plastic use

- Less chance of splashing with low-viscosity liquids

- Possibility for effective nitrogen flushing

- Small footprint and high efficiency

- Food contact area: hygienic area designed for food products applications

- Continuous motion filling enables a longer filling time. The linear and continuous motion of the filling nozzles enables the filling time to reach up to 1.5 seconds. 3x longer compared to other machines. Improving filling accuracy and reducing splashing of the product

- Ability to work with four different caps at the same time

Product benefits

The self-lubricating steel chain ensures seamless operations and low maintenance, allowing you to focus on delivering excellence.

The expandable module design enables multiple filling stations for increased product varieties and multipacks.

In-motion filling through spout enables maximized overall volume for increased productivity. For low viscosity products, splashing is reduced while maintaining clean and fast operations.

How it works

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-clean (ESL)

Uses UV and/or hydrogen peroxide in combination with laminar flow to achieve high hygienic levels for short shelf-life products.

Hot-fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| mL | Liters per minute | Maximum pouches per minute |

| 500.0 | 60 | 240 |

Typical categories

- Alcoholic beverages

- Automotive fluids

- Baby & toddler food

- Beauty & personal care

- Beverage concentrates

- Cleaning solutions

- Coffee & tea

- Condiments

- Crop protection

- Edible oil

- Fruits & vegetables

- Functional dairy

- Juice-based drinks

- Meal replacements

- Paint & coatings

- Plant-based

- Sauces

- Smoothies

- Soft-serve ice cream

- Soup

- Spreads & toppings

- Water

- Yogurt

- Yogurt drinks

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions

Market successes

FirstWave offers unparalleled flexibility with aseptic pouches

FirstWave offers unparalleled flexibility with aseptic pouchesLooking for a co-packer?