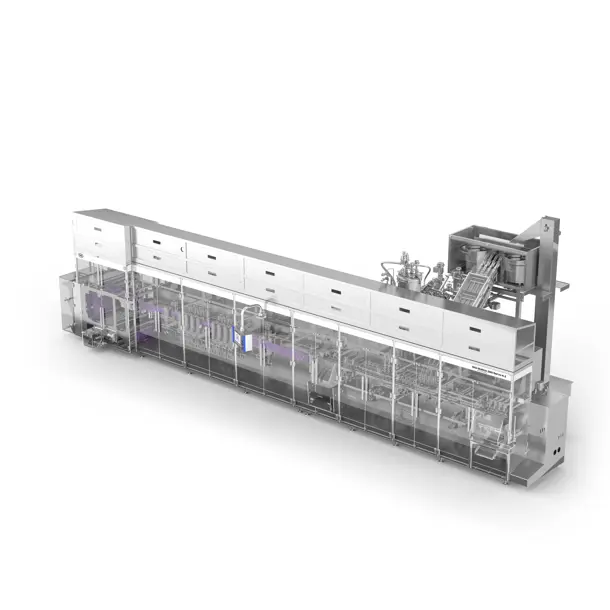

Meet the SIG Motion Servo Series

Engineered to transform your production process, the SIG Motion Servo Series sets a new standard for efficiency, accessibility, and sustainability. The SIG Motion Servo Series is known for its innovative transmission system, a patented technology that allows for multiple independent axis movements.

- Fewer mechanical parts than traditional single cam shaft systems

- Servo technology results in higher quality pouches

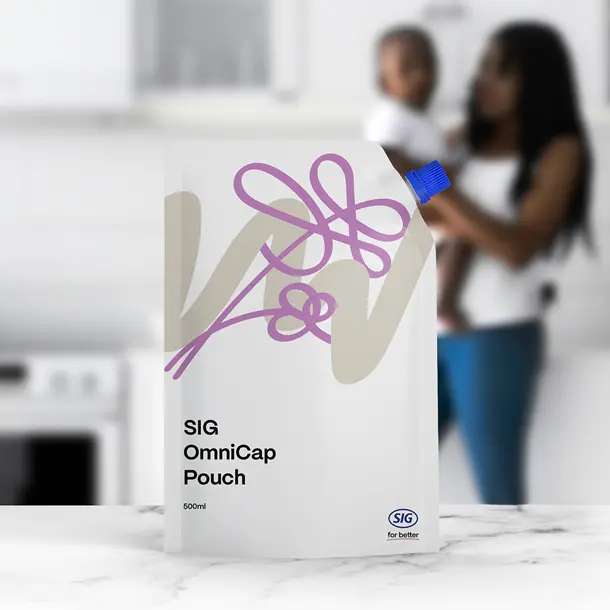

- Ability to create different shapes and designs to increase shelf appeal

Key features

The SIG Motion Servo Series uses state-of-the-art technology and is servo-controlled. The multiple-axis movements are independently controlled by a patented transmission system. This machine is intelligent, reliable, easy to operate, and requires little maintenance. It offers:

- Better accessibility for easier maintenance

- A 3D touchscreen

- Automatic alignment and pouch width correction system

- An instruction manual, as well as electronic and pneumatic diagrams, available on the touchscreen

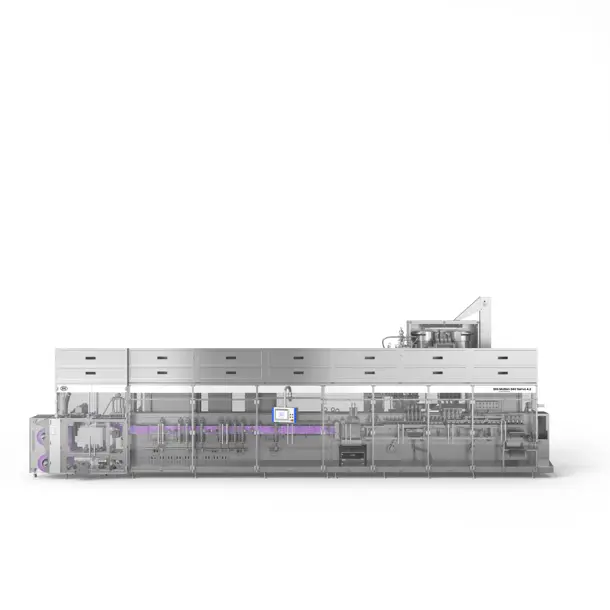

- Up to 10% productivity increase over typical mechanical HFFS machines

- Less maintenance due to less wearing parts

- Pouch seal quality comparable to pre-made pouches

- Sanitary construction

- Energy efficiency with excess power being sent back to the grid

- The latest technology with optical fibers, optical barriers, position sensors, seal quality sensors, vision cameras, and more

Product benefits

Thanks to full servo technology, the SIG Motion Servo Series increases productivity up to 10% compared to mechanical HFFS.

With fewer mechanical parts, the SIG Motion Servo Series offers hassle-free operation, while sanitary construction further streamlines upkeep and ensures operational excellence.

Servo-driven engines harness excess power, channel it back into the grid, which amplifies energy efficiency and reduces energy consumption.

How it works

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-clean (ESL)

Uses UV and/or hydrogen peroxide in combination with laminar flow to achieve high hygienic levels for short shelf-life products.

Hot-fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| mL | Liters per minute | Maximum pouches per minute |

| 500.0 | 60 | 240 |

Product variations

This HFFS machine works in simplex and duplex, forming and filling pouches up to a maximum aggregated width of 160mm. It can fill up to 120 pouches per minute and up to 1200mL.

This HFFS machine works in simplex and duplex, forming and filling pouches up to a maximum aggregated width of 220mm. It can fill up to 120 pouches per minute and up to 2000mL.

This HFFS machine works in simplex and duplex, forming and filling pouches up to a maximum aggregated width of 260mm. It can fill up to 120 pouches per minute and up to 2500mL.

This HFFS machine works in simplex, duplex, and triplex, forming and filling pouches up to a maximum aggregated width of 330mm.. It can fill up to 180 pouches per minute and up to 1500mL.

This HFFS machine works in duplex and quadruplex, forming and filling pouches up to a maximum aggregated width of 420mm at speeds up to 240 pouches per minute.

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions

Market successes

FirstWave offers unparalleled flexibility with aseptic pouches

FirstWave offers unparalleled flexibility with aseptic pouchesLooking for a co-packer?