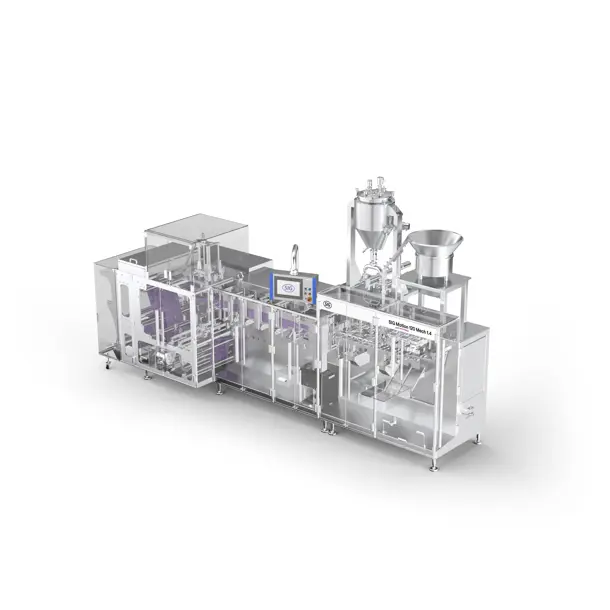

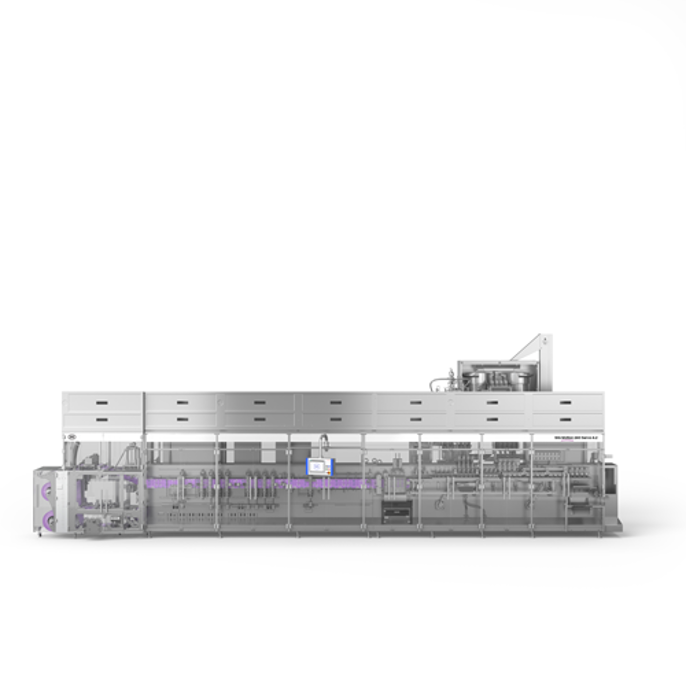

Unparalleled adaptability

Embark on a journey of unparalleled adaptability with the SIG Motion Mech Series. This HFFS machine redefines versatility through its standardized modules and enhanced features, seamlessly tailored to accommodate diverse filling systems and fitments.

Key features

The SIG Motion Mech Series sets a new standard for HFFS technology through its modular frame construction. Comprised of three distinct, yet seamlessly integrated, modules, this series redefines versatility, precision, and adaptability in packaging solutions.

- Unwind module: ensures the steady unwinding of pouch films with impeccable tension control and material handling

- Pouch forming module: transforms film into customized pouches

- Filling module: features a hygienic design and easy to dismantle system, the SIG Motion Mech Series works with different dosing systems

With two filling stations, you can simultaneously fill multiple products into a single pouch, elevating efficiency and convenience.

Each model within the series is equipped with standardized modular groups and enhanced features, ensuring a seamless adaptation uniquely suited to your product.

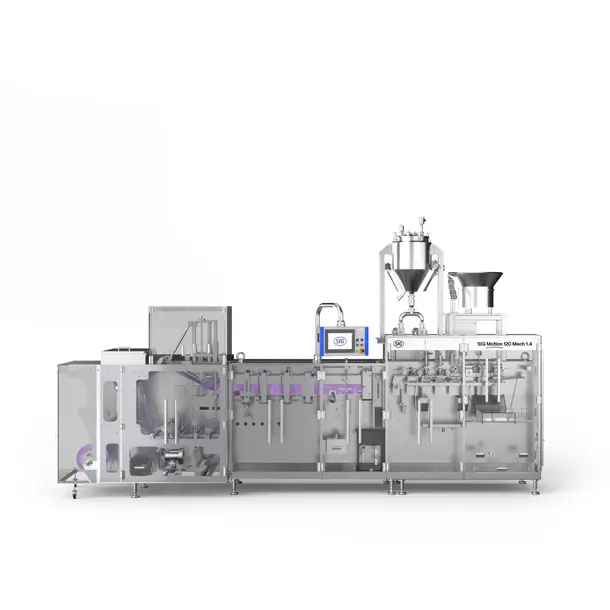

Product benefits

Standardized groups and enriched features across all models ensure a harmonious fit with any filling method or fitments.

Top sealing and cooling groups designed with 180º folding allow easy access for cleaning, which minimizes downtime and optimizes operational efficiency.

Customize your sealing dimensions with our optional automated size adjustment via an intuitive touchscreen interface. Individual control of seal jaw temperature ensures consistent, high-quality seals.

Simplify transitions between setups without needing to adjust seal bars during changeover. The SIG Motion Mech Series' removable walking beam allows for rapid format change, minimizing interruptions and maximizing productivity.

How it works

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-clean (ESL)

Uses UV and/or hydrogen peroxide in combination with laminar flow to achieve high hygienic levels for short shelf-life products.

Hot-fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| mL | Liters per minute | Maximum pouches per minute |

| 500.0 | 60 | 240 |

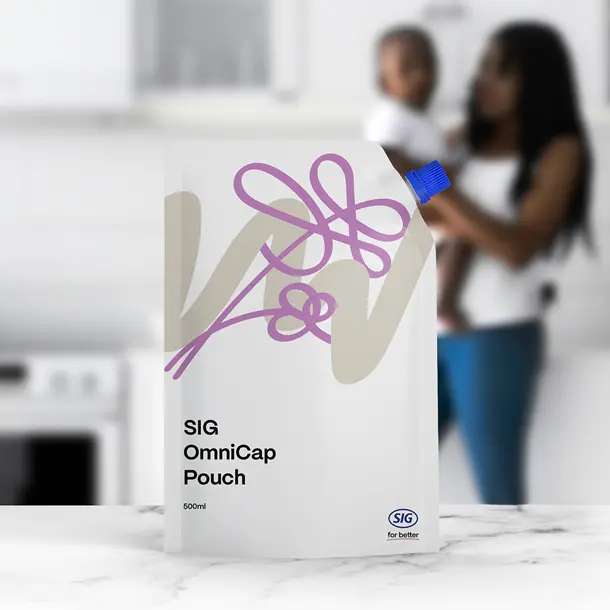

Typical categories

- Alcoholic beverages

- Automotive fluids

- Baby & toddler food

- Beauty & personal care

- Beverage concentrates

- Cleaning solutions

- Coffee & tea

- Condiments

- Crop protection

- Edible oil

- Fruits & vegetables

- Functional dairy

- Juice-based drinks

- Laundry care

- Meal replacements

- Paint & coatings

- Plant-based

- Sauces

- Smoothies

- Soft-serve ice cream

- Soup

- Spreads & toppings

- Water

- Yogurt

- Yogurt drinks

Product variations

This HFFS machine forms and fills pouches up to a maximum aggregated width of 140mm. It can fill up to 120 pouches per minute and up to 750mL.

This HFFS machine forms and fills pouches up to a maximum aggregated width of 200mm. It can fill up to 120 pouches per minute and up to 1500mL.

This HFFS machine forms and fills pouches up to a maximum aggregated width of 260mm. It can fill up to 120 pouches per minute and up to 2500mL in simplex and 750mL in duplex.

This HFFS machine forms and fills pouches up to a maximum aggregated width of 330mm. It can fill up to 120 pouches per minute and up to 2500mL in simplex and 1200mL in duplex.

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions

Market successes

FirstWave offers unparalleled flexibility with aseptic pouches

FirstWave offers unparalleled flexibility with aseptic pouchesLooking for a co-packer?