Flexibility in every way

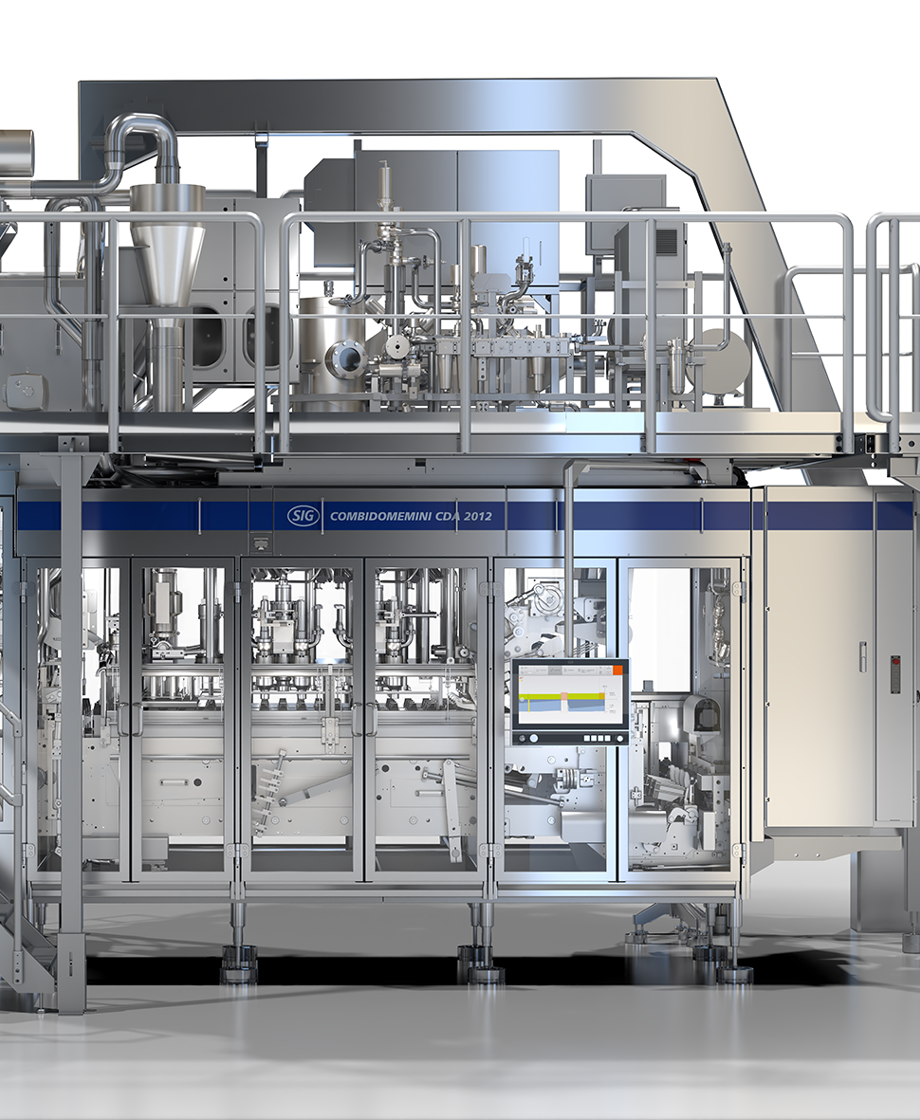

SIG’s filling technology is marked by unrivalled flexibility. Provided the same base dimensions, we offer the industry's fastest change-over times for formats, volumes, and designs. Within a few minutes, our machines can be adapted to handle up to nine different carton volumes. Our filling machines are also compatible with a wide range of other equipment from third-party manufacturers, giving you full flexibility over your technology partners.

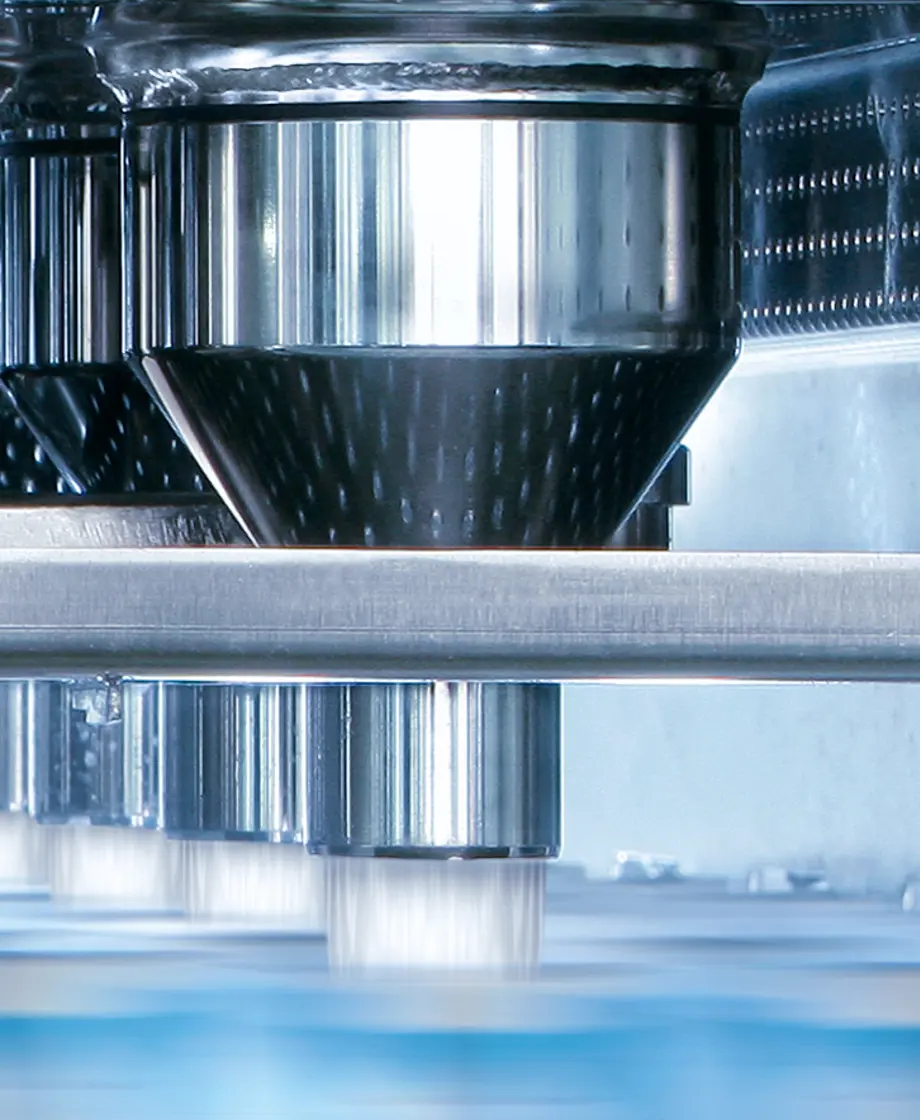

The aseptic advantage

Aseptic filling ensures the highest food safety standards and quality, helps retain nutrients, flavors, and colors.

- Shelf life of up to 12 months without refrigeration or preservatives

- Our open-sleeve filling process also ensures a wide range of products to be aseptically filled

High efficiency, low waste rate

With the ability to fill up to 24,000 packs per hour, our filling machines meet highest performance criteria for food and beverage producers. This speed, combined with unrivaled, low wastage rates and unique flexibility results in high effectiveness and low overall system costs.

And, thanks to their robust, well-engineered construction, you can be sure that the machines run reliably for many years. With our standard filling machines, we can fill three main product segments in our standard carton packs – liquid dairy and plant-based beverages, non-carbonated soft drinks (NCSD), and liquid food products.

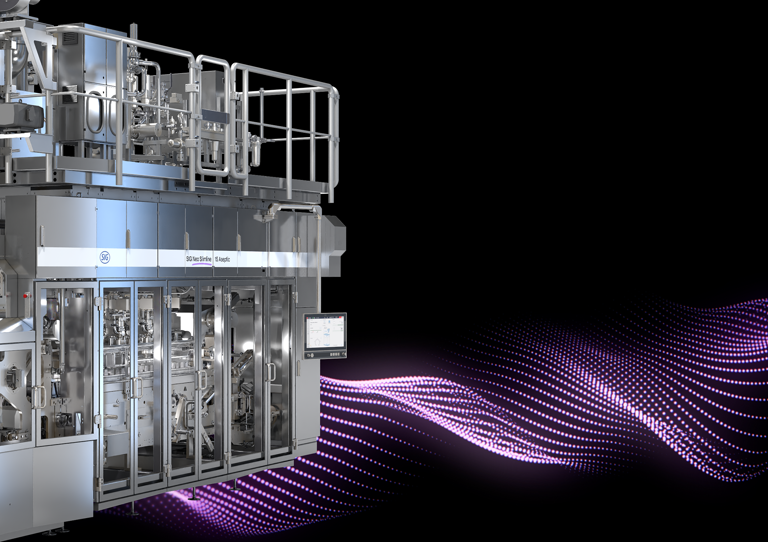

SIG Neo. The next big step in aseptic technology

SIG is expanding its SIG Neo filling machine portfolio launching another cutting-edge filling machine for multi-serve aseptic carton packs, capable of filling up to 15,000 SIG SlimlineBloc packs per hour – a 25% increase in output compared to SIG’s standard filling machines for family-sized formats.

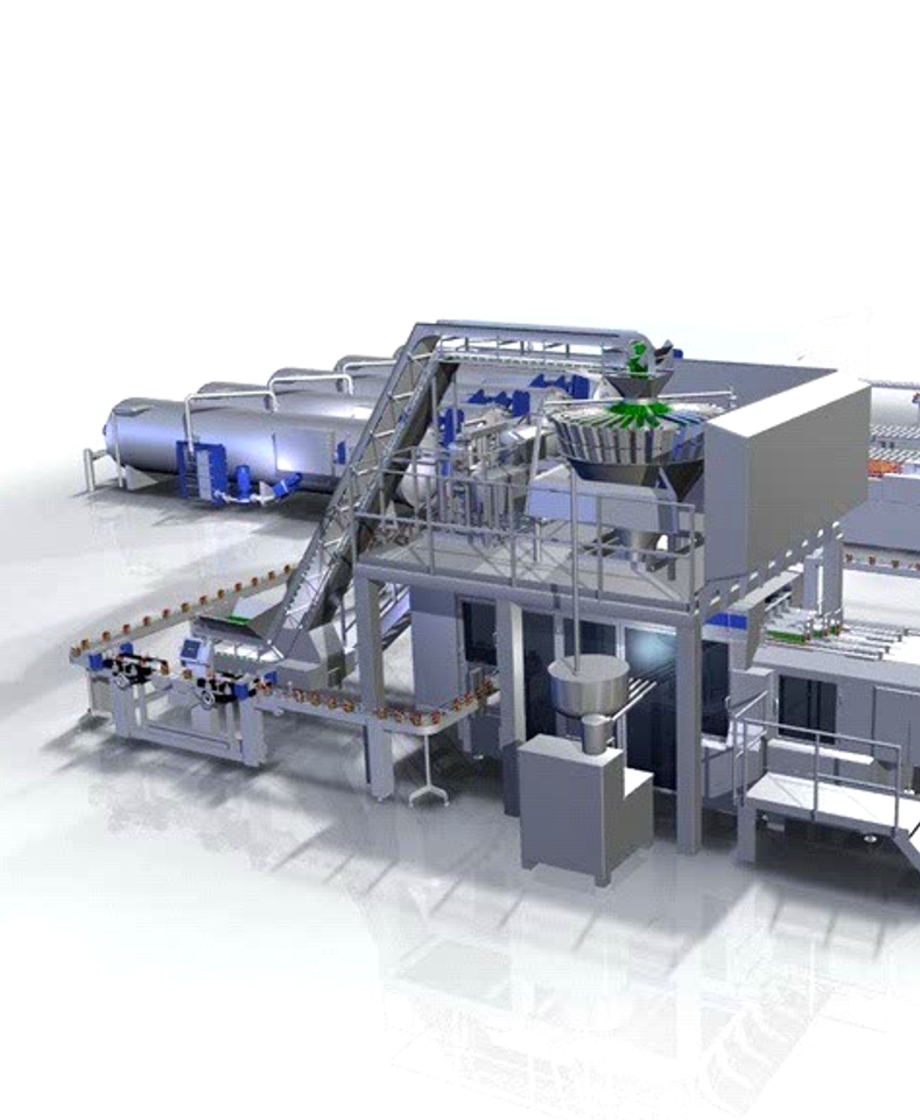

Food filling options by SIG

Our open-sleeve filling process ensures a wide range of possibilities for your products: with our standard filling machines, we can fill three key product segments in our standard carton packs – liquid dairy and plant-based beverages, non-carbonated soft drinks (NCSD), and liquid food products. To add value to any product, we offer additional kits to increase the number of products that can be filled on our standard filling machines: SIG Drinksplus solution to add value to any beverage and Food Options to extend the possibilities with liquid food products.

For food products with particulates up to 25mm, we use special food structures and filling machines. And we go even beyond this and offer a retort system for all products that cannot pass through an aseptic process.