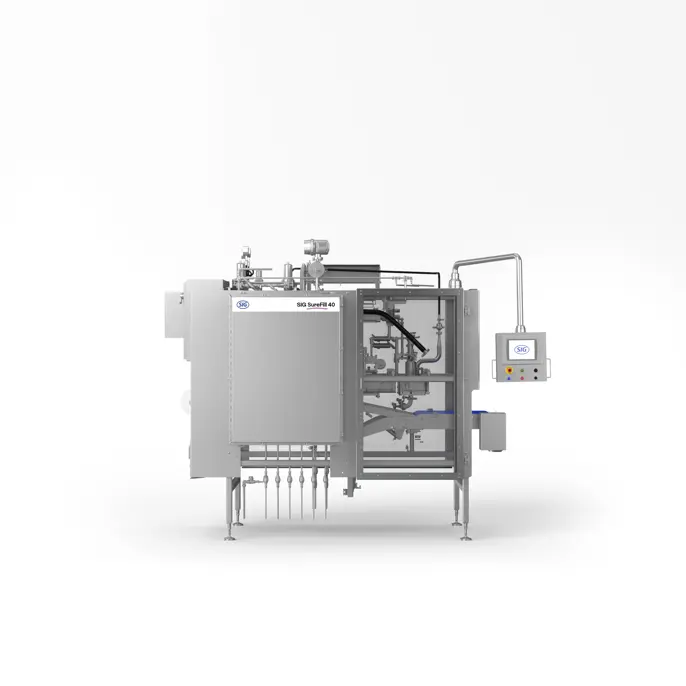

Fit-for-purpose filling

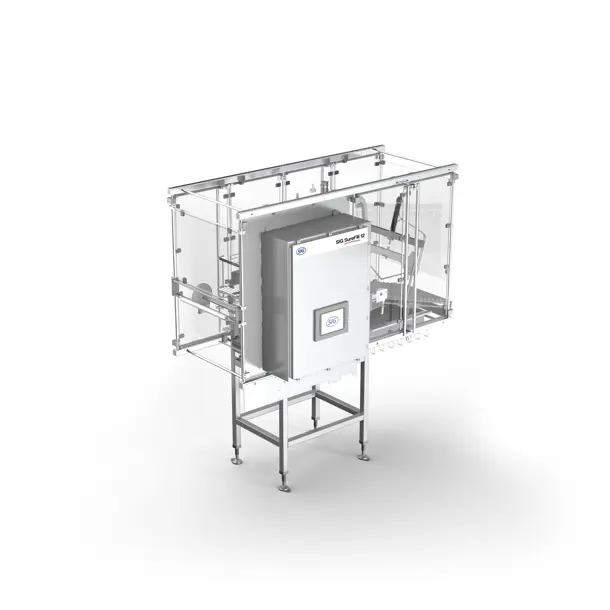

With its compact design, the SIG SureFill 12 maximizes efficiency without compromising on performance. This solution offers precise filling, user-friendly operation, and consistent product quality, making it the ideal choice for a wide range of liquid product applications.

Key features

The SIG SureFill 12 is a single-lane, automatic web filling machine capable of packaging ambient products in from 1.5 to 22 liters. The filler is equipped with an Allen Bradley PLC interface utilizing panel view plus HMI. To ensure optimal process conditions, this interface system also includes optional visual warning indicators as well as a messaging system that displays fault condition(s) and can, if necessary, stop the filling operation. Product can also be automatically diverted away from the filler with messaging to upstream processing control.

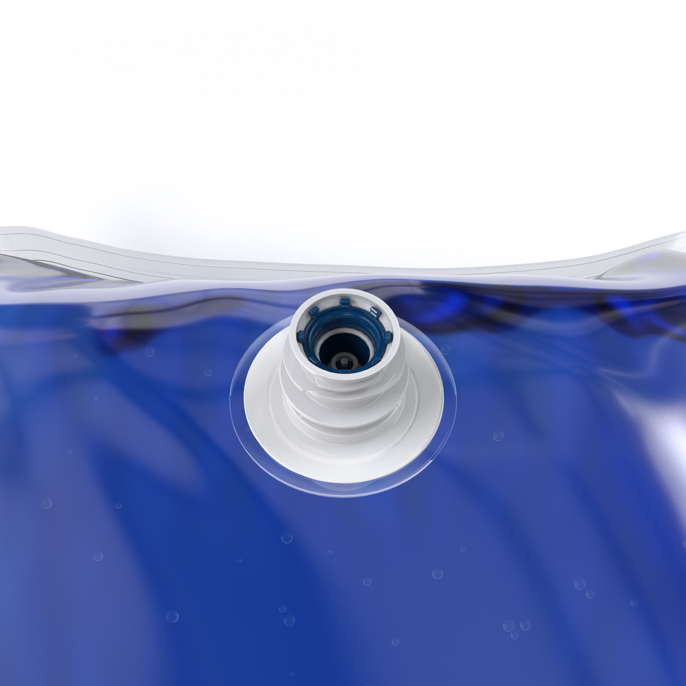

The SIG SureFill 12 has a modular design and can be configured to address a variety of packaging and bag loading options - from flat drop to end loading configurations. All product contact surfaces are constructed out of 316L stainless steel and are assembled with food grade construction.

Product benefits

The SIG SureFill 12 maximizes production efficiency with its compact design and quick changeover capabilities.

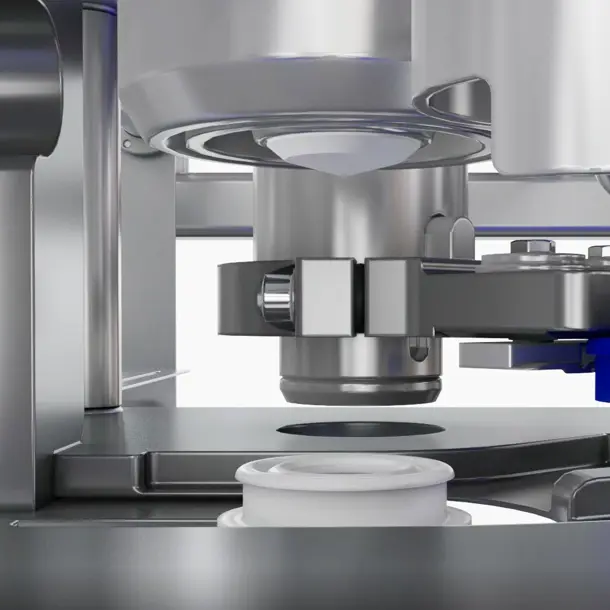

With its precise filling (within .5 of a percent) the SIG SureFill 12 ensures accurate dosing and consistent product quality.

With an easy-to-use HMI, the SIG SureFill 12 keeps things simple and easy to operate.

The integrated control system of the SIG SureFill 12 ensures reliable performance and consistent production output.

How it works

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| (L) | (Liters per Minute) | (Bags per Minute) |

| 2.0 | 227 | 14-15 |

| 3.0 | 227 | 14-15 |

| 4.0 | 227 | 13-14 |

| 5.0 | 227 | 10-12 |

| 10.0 | 227 | 9-11 |

| 20.0 | 227 | 7-8 |

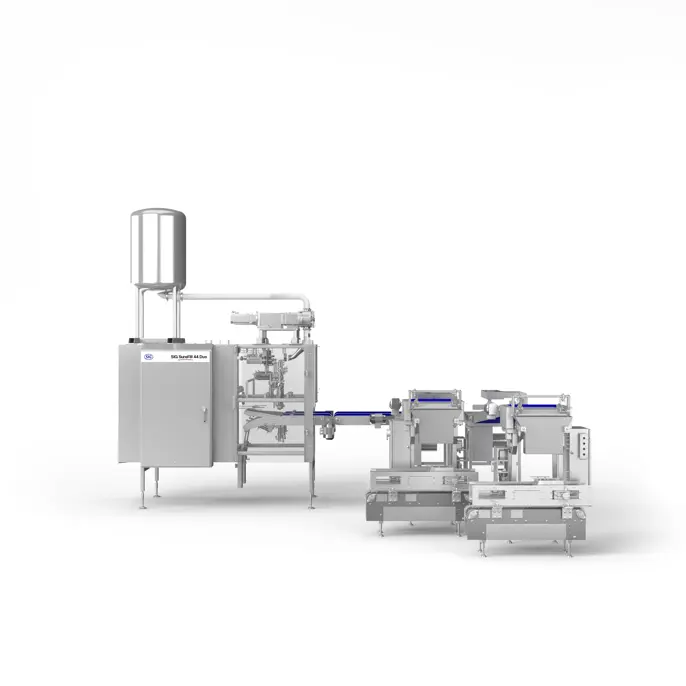

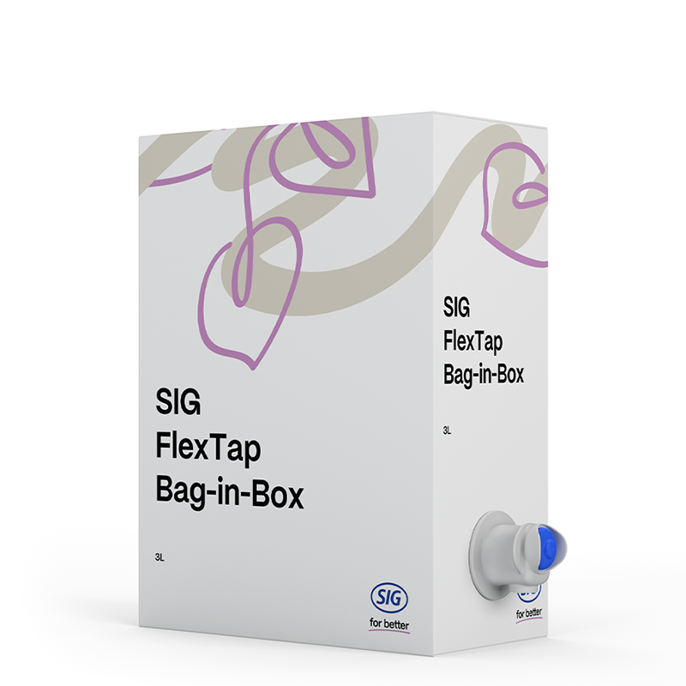

Product variations

Built to fill and seal within a nitrogen positive chamber to reduce oxygen in headspace, designed with wine in mind.

Built with HEPA filtration, designed with ozonated water in mind.

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions

Market successes

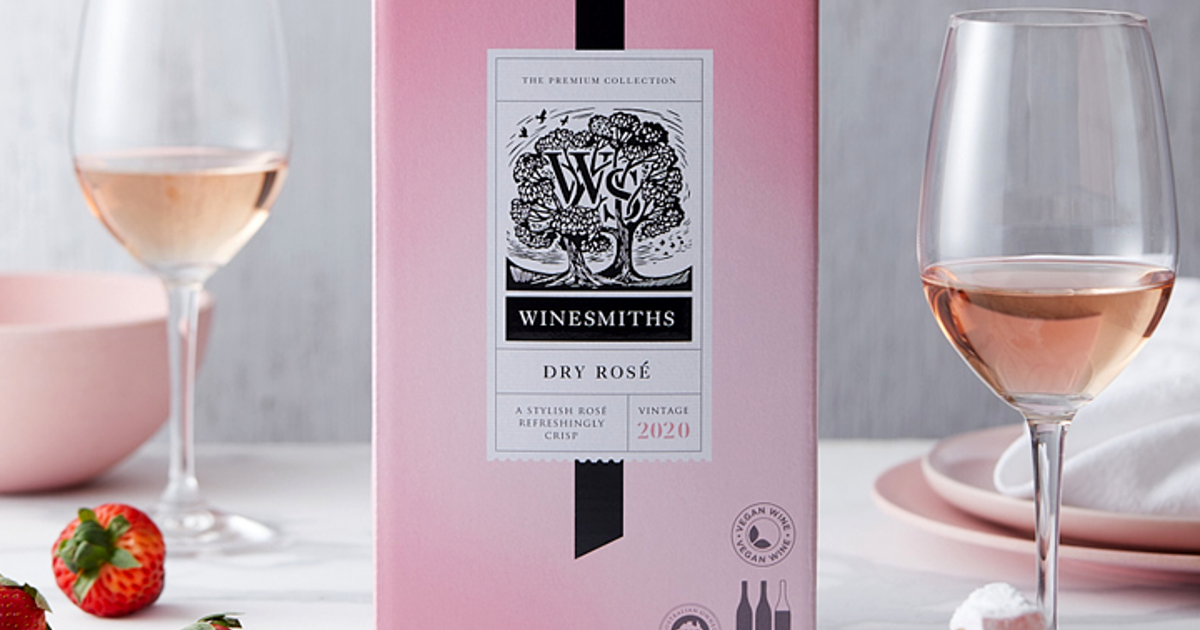

A toast to success with Winesmiths

Read moreLooking for a co-packer?