Your trusted filling solution

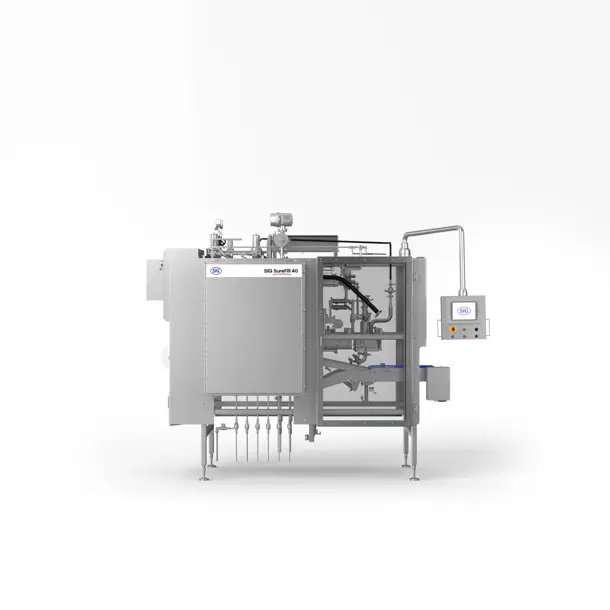

The SIG SureFill 40 is a state-of-the-art bag-in-box filling equipment that combines speed, accuracy, and reliability to meet the demands of your packaging operations. With its advanced technology and user-friendly interface, it enables efficient and precise filling of liquid products.

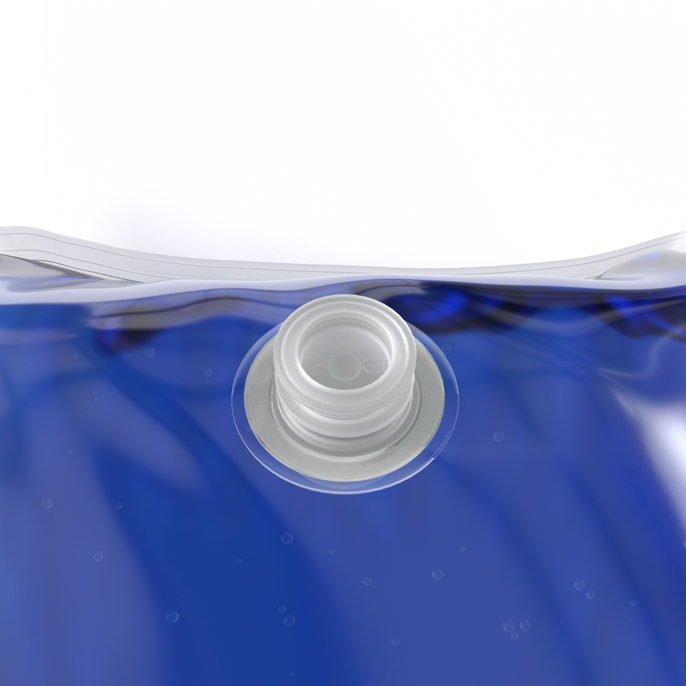

- Ensures optimal product quality and shelf life

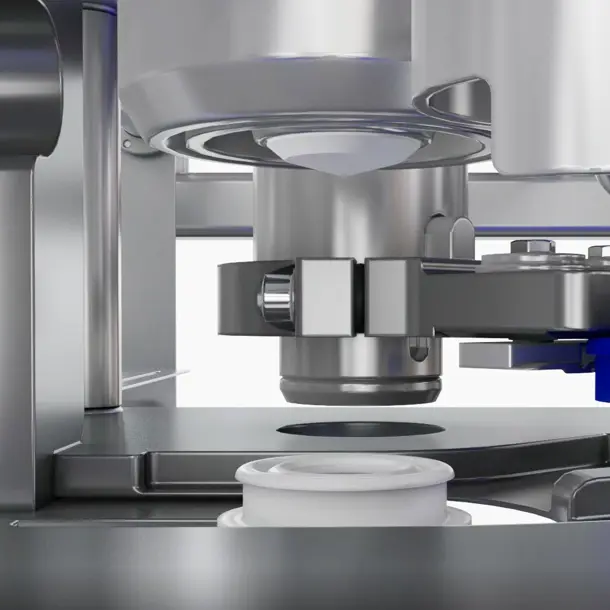

- Features patented sterilization technology

- Keeps your products safe and sterile throughout filling process

Key features

The SIG SureFill 40 is a single-lane, automatic web filling machine. The machine is capable of packaging extended shelf life (ESL), high-acid (HA), and low-acid (LA) products in 3- to 20-liter bag-in-box sizes. The filler is equipped with an Allen Bradley PLC interface utilizing panel view plus HMI. To ensure optimal process conditions, this interface system also includes optional visual warning indicators as well as a messaging system that displays fault condition(s) and can, if necessary, stop the filling operation. All product contact surfaces are constructed out of 316L stainless steel.

This system has optional visual warning indicators; a messaging system that displays fault condition(s) and, if necessary, stops the filling operation. In addition, if necessary, product may be automatically diverted away from the filler with messaging to upstream processing control.

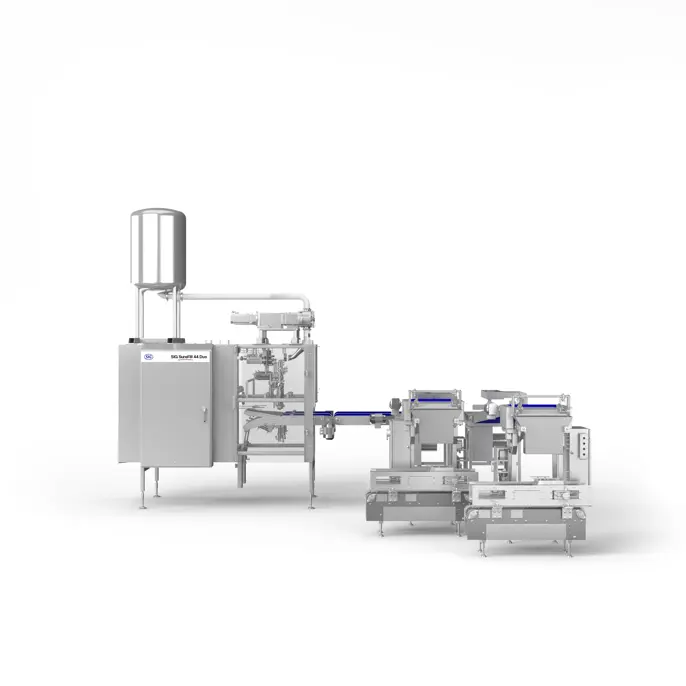

This filler is of modular design and can be configured to address a variety of packaging and bag loading options: from flat drop to end loading configurations.

Product benefits

The SIG SureFill 40 maximizes production efficiency with its compact design and quick changeover capabilities.

With its precise filling (within .5 of a percent) the SIG SureFill 40 ensures accurate dosing and consistent product quality.

With an easy-to-use HMI, the SIG SureFill 40 keeps things simple and easy to operate with minimal training.

The integrated control system of the SIG SureFill 40 ensures reliable performance and consistent production output.

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-clean (ESL)

Uses UV and/or hydrogen peroxide in combination with laminar flow to achieve high hygienic levels for short shelf-life products.

Aseptic

Fills commercially-sterilized products into pre-sterilized packaging. Products can be held unopened without refrigeration.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| (L) | (Liters per Minute) | (Bags per Minute) |

| 3.0 | 227 | 13-15 |

| 4.0 | 227 | 12-14 |

| 5.0 | 227 | 11-13 |

| 10.0 | 227 | 9-10 |

| 20.0 | 227 | 6-7 |

Typical categories

- Alcoholic beverages

- Automotive fluids

- Baby & toddler food

- Beauty & personal care

- Beverage concentrates

- Cleaning solutions

- Coffee & tea

- Condiments

- Cream

- Edible oil

- Fruits & vegetables

- Functional dairy

- Juice-based drinks

- Meal replacements

- Paint & coatings

- Plant-based

- Sauces

- Smoothies

- Soft-serve ice cream

- Spreads & toppings

- Water

- White milk

- Yogurt

- Yogurt drinks

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions

Looking for a co-packer?