Soluciones avanzadas de envasado para verduras procesadas

Comodidad y calidad

Equilibra la facilidad de uso para los procesadores con una consistencia fiable y la integridad del sabor para los usuarios finales.

Versatilidad de la industria

Soluciones flexibles de envasado de 20 L a 1300 L para diversas ofertas de verduras procesadas.

Tecnología de envasado aséptico

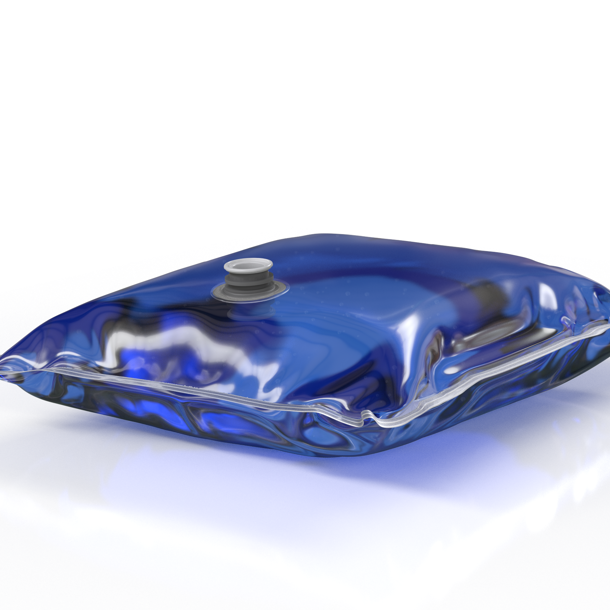

Rellenar, almacenar y descargar verduras procesadas asépticamente con bag-in-box aséptico a granel que prolonga la frescura del producto mucho más allá de la temporada de cosecha.

Envase Bag-in-box para verduras procesadas

- Tecnología de embalaje aséptico para carga, almacenamiento y descarga a granel

- Mejora de la vida útil de los productos alimenticios gracias a la trazabilidad

- Soluciones que minimizan su impacto medioambiental y dejan menos residuos de envases

- Reducción del desperdicio de alimentos con una vida útil secundaria más larga y una extracción máxima del producto

Con el embalaje aséptico, usted puede entregar un producto vegetal fresco y natural —sin sabores o conservantes “cocidos”— con una vida prolongada y sin necesidad de igeración. Nuestros innovadores sistemas de bolsa en caja incluyen una amplia gama de películas, accesorios y equipos de llenado para una solución completa de embalaje diseñada para proteger sus productos de llenado a través del uso final. Además, con tecnología de embalaje aséptico, puede extender la frescura de sus hortalizas mucho más allá de la temporada de cosecha con la capacidad de cargar, almacenar y descargar asépticamente.

En la restauración, puedes dispensar de forma segura productos vegetales procesados como partículas, concentrados y pastas con nuestros sistemas de circuito cerrado con capacidad aséptica que minimizan las oportunidades de contaminación durante el uso y prolongan la frescura tras la apertura. Nuestros productos institucionales bag-in-box se han diseñado teniendo en cuenta el rápido ritmo de la restauración:

- Mangueras sencillas y sistemas de conexión rápida para una dispensación fiable

- Fácil de desconectar y con menos suciedad para los protocolos de limpieza de surtidores

- Evacuación mejorada para maximizar los beneficios y minimizar los residuos

Utiliza nuestros IBC flexibles de tamaño industrial, tote liners y drum liners para transportar de forma segura tus productos vegetales procesados en envases que ofrecen un ahorro de costes en toda la cadena de suministro. Nuestros envases industriales facilitan:

- Entrega limpia y segura del material desde y hacia su planta de producción

- Optimización, que exige menos recursos para limpiar y mantener los contenedores a granel

- Eliminación de la necesidad de recurrir a la cadena de frío gracias a la capacidad de llenado, almacenamiento y vaciado asépticos

El envase Bag-in-box es ideal para...

Technology/value headline

Estamos en camino de crear envases for better

Sistemas de envasado regenerativos con resultados positivos para las personas y el planeta

Le ofrecemos valor pensando de principio a fin. Siempre.

Más información sobre nuestras soluciones, desde innovación de productos hasta sistemas de envasado y producción inteligente.

¿Buscas un co-packer?