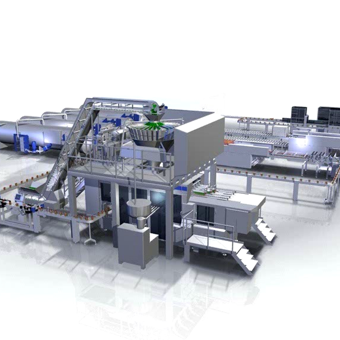

Key features

SIG Retort Food filling machines ultrasonically seal the carton packs above the filling level, ensuring that fibers and pieces of food cannot get caught in the seal area and potentially compromise the product quality. After filling, the carton packs are transported to autoclaves, where packages and product are sterilized together.

- Variable output of up to 12,000 packs per hour

- Flexibility: 5 volumes on one filling machine: 200ml, 300ml, 400ml, 440ml, and 500ml

- Quick volume change in just a few minutes

- Multi-head weigher for precise portioning and cost-effective production

- Three-stage filling system for a wide variety of products and recipes.

- up to 40mm particulates, 50% solid content and more, up to 5,000 mPas/cps

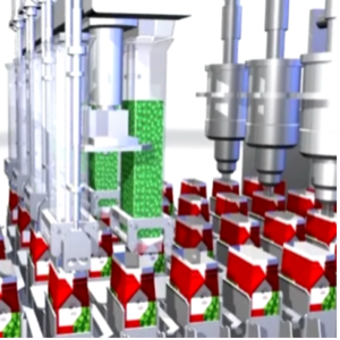

Three-stage filling process

We developed an innovative three-stage process that starts by filling the SIG SafeBloc carton pack with products that can be pumped, then the weighed pieces are added. In the third stage, the package is topped up with a liquid. This method makes your production process very cost-effective because you can add individual product ingredients to the recipe continuously and in exactly the right quantities. This precision also gives you better control over product costs.

Package sizes

Rotary or static autoclave

The autoclave can be either static or rotary, depending on your preferences and the requirements of the product. Rotary autoclaves provide optimum temperature distribution inside the carton pack and improve product taste and quality.