Key features

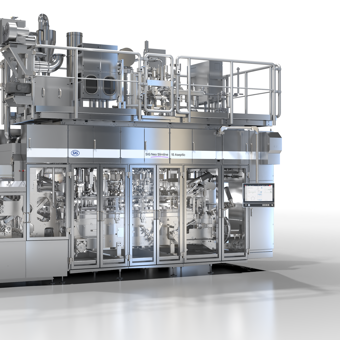

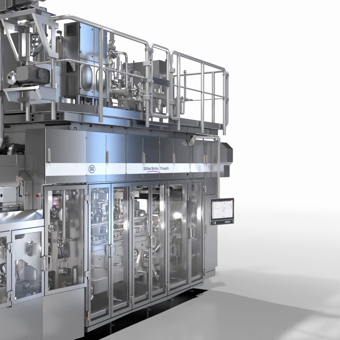

The new SIG Neo Slimline 15 Aseptic machine not only accelerates production speed, but also maintains a compact footprint, making it an ideal solution for producers looking to increase capacity without costly facility expansions. In an industry where floor space is at a premium, flexibility and quality are essential and the total cost of ownership is a priority, SIG’s ability to significantly boost output per square meter is a game-changer.

The SIG Neo technology represents a major leap forward in filling machine innovation. Designed to meet the evolving needs of the F&B sector, it enables manufacturers to seamlessly switch between 1L, 750mL and 500mL packaging volumes, products from multiple categories and packaging materials.

- Flexibility: 3 volumes on one filling machine: 500ml, 750ml and 1,000ml

- Up to 15,000 packs/hour ; up to 70 million packs/year

- Automated processes: Single-pack ejection for even less waste

- Full flexibility with regards to changing volumes and package design; suitable to fill different product categories

- Ready to run our SIG Terra suite of even lower carbon aseptic carton packaging materials

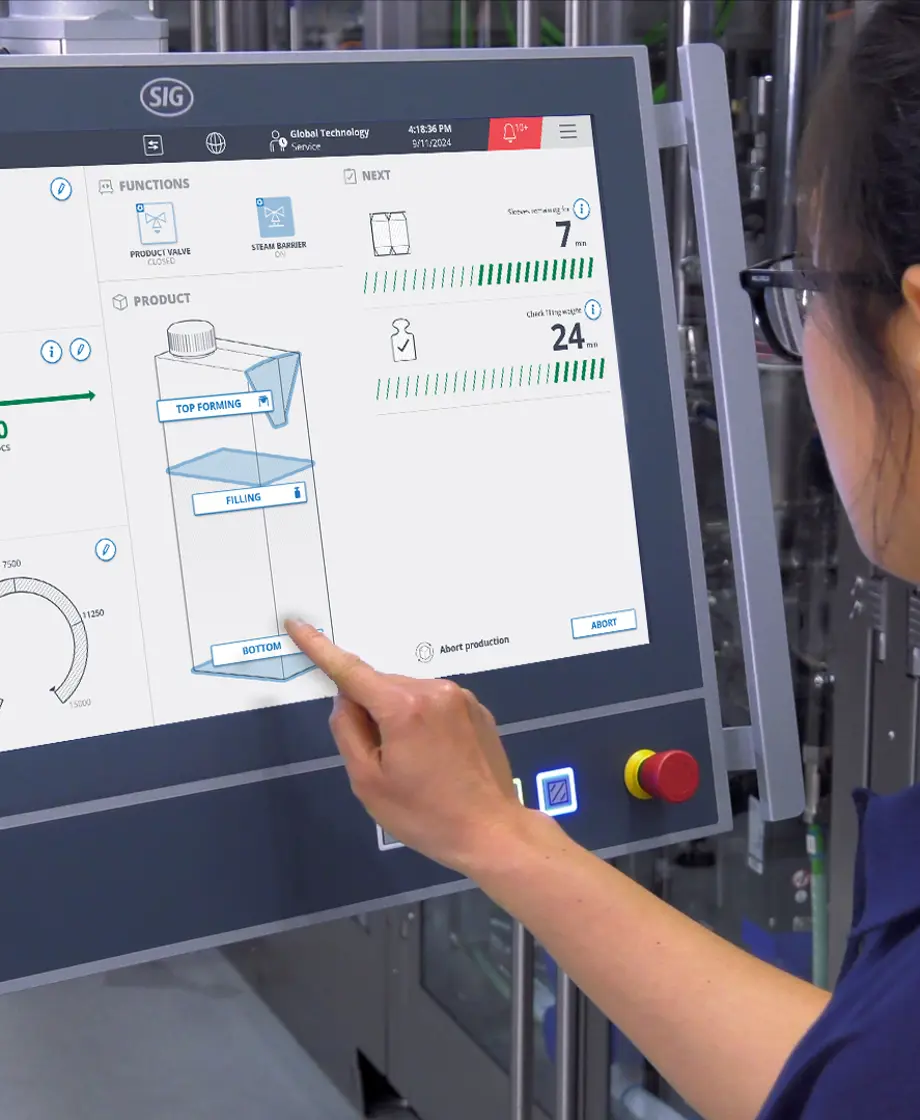

SIG Neo HMI

The SIG Neo Slimline 15 Aseptic machine includes the state-of-the-art SIG Neo HMI for intuitive operation and to generate smart insights on the performance of the filling machine.

Additional options to boost performance

Additional options include SIG Neo Shield for enhanced sterile airflow and shielding during bottom sealing and pre-folding making it possible to remove up to 95% particles from the air, leading to top quality and extended production cycles.

Furthermore, semi-automatic cleaning capabilities will be included on the SIG Neo platform providing superior cleaning results and shorter downtime.

SIG Neo RoboFeed

With the SIG Neo RoboFeed, sleeve pallets can be easily inserted through a sliding door. The feeding of the sleeves to the filler magazine is controlled by a three-axis servo drive system.