Key features

Provided the same base dimensions, we offer the industry's fastest change-over times for formats, volumes and design. Our filling machines offer both high performance and low overall system costs, combined with low waste rates and unique flexibility. And thanks to their robust, well-engineered construction, the machines will continue to run reliably for many years.

SIG Magnum 9 Aseptic

- 2 Formats on one machine

- Changing formats in just a few minutes

- Changing package design without interrupting the filling process

- Up to 9,000 packs / hour

- One trained operator can run the machine

SIG MaxiBloc 6 Aseptic

- 5 volumes on one machine (1,000ml, 1420ml, 1,500ml, 1,893ml, 2,000ml)

- Volume changes within just a few minutes

- Wide range of products can be filled - ideal sizes for food service

- 6,000 packs / hour

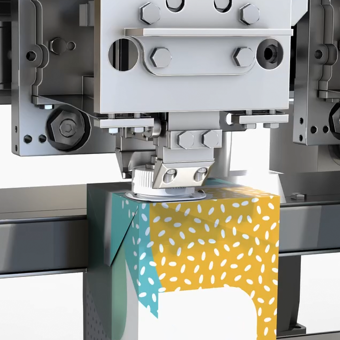

SIG Applicators

- SIG Bloc Cap Applicator: The post-application of the spouts with an applicator makes it possible to fill different formats on one line and increase the aseptic safety.

- SIG Bloc/Fit Cap Applicator: For filling machines, which can fill two different formats, the applicator also forms the package after the filling process and gives it the final shape.

Formats and matching filling machines

SIG Magnum

SIG Magnum 9 Aseptic

SIG MaxiBloc

SIG MaxiBloc 6 Aseptic