At SIG, we're problem solvers. We don't simply sell packaging solutions, but work with our clients to identify opportunities for better packaging formats and systems that reduce waste and improve efficiency—and sometimes, along the way, our solutions allow our partners to expand into new markets.

Daus (previously known as Ourolac) is one of Brazil's leading dairy foods producers, focusing on milkshake and dessert products for quick-serve restaurants and out-of-doors retailers. Since 2002, Daus has produced their products using UHT and aseptic processing. Ice cream lovers in South America can find Daus products in quick-serve restaurants like KFC, Bob's, Burger King, and Giraffa's.

The challenge: updating outdated systems

Daus challenged us to help them reduce costs incurred by packaging losses—basically, they were losing product due to a lack of packaging structural integrity and inefficiency on their line. They were using a legacy form-fill-seal packaging system at the time, so we switched them to SIG's bag-in-box fillers and packaging.

The solution: a fully-integrated packaging line

Our solution included setting them up with a highly engineered film, a user-friendly fitment, and state-of-the-art filling equipment for a total packaging solution designed to suit their unique needs. As we worked together, Daus even realized they could work with us to launch a new ice cream product and utilizing SIG’s packaging solutions.

We delivered a new packaging system to Daus in three steps:

- Film: Daus’ milkshake base product had some weight, so the film we chose needed to be durable. We selected a combination of FlexiTuff and HyBar for their combined seal strength and ability to hold up throughout rigorous aseptic filling and delivery logistics.

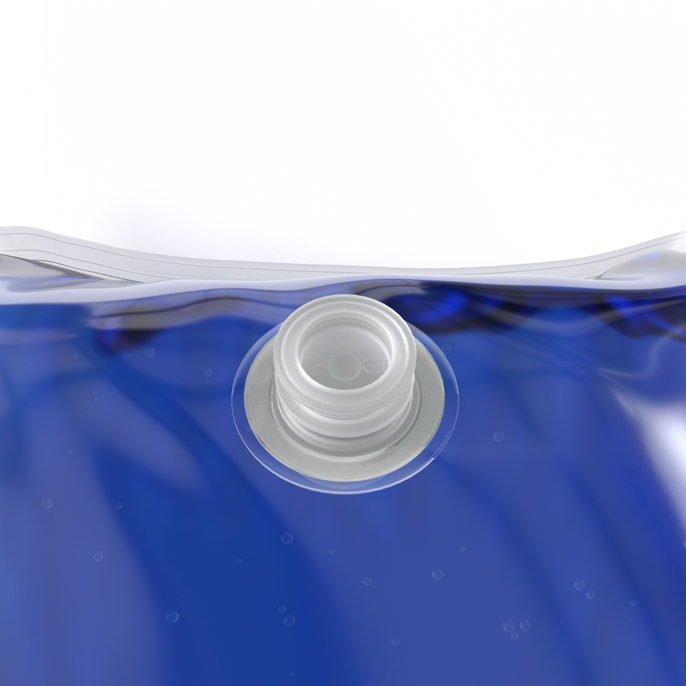

- Fitment: We matched Daus with our SIG Terra PourCap1400 for its ease-of-use and ability to remain hermetically sealed from the moment the bag-in-box package is filled through to when it’s opened at the restaurant. The fitment’s performance is critical to Daus’ success, as aseptically-packaging goods do not rely on cold chain logistics. Instead, these products are shipped in an ambient atmosphere, with tremendous economic and environmental savings.

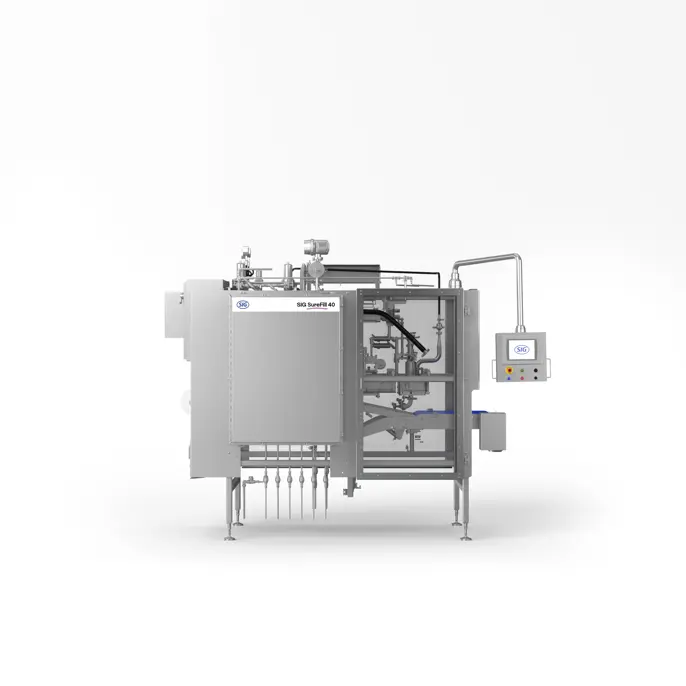

- Equipment: We equipped Daus with a SureFill 30 and SureFill 40. These filling machines can handle various bag-in-box sizes and fitment options, allowing them to add new products and formats as their business and the marketplace evolve.

The result: say goodbye to cold storage costs

Aseptic packaging is a big part of what we do at SIG—eliminating cold chain storage helps protect the environment and cuts costs, delivering a win-win to partners like Daus.

By focusing on improving their packaging and aseptic capabilities, we helped Daus:

- Enter the ice cream market due to the durability of their new packaging format

- Eliminate waste generated from outdated equipment

- Save on cold storage and energy costs by implementing a strong, aseptic packaging program

- Provide preservative-free products that stay fresh for up to 12 months on the shelf

To learn more about the difference between an aseptic and cold-chain supply model, visit our sustainability page.

Featured products