In 2012, SIG was the first company to release bag-in-box packaging for the lubricant sector. Since then, we have evolved into an industry leader in packaging for motor oils and other automotive fluids. With continuous improvement and innovation embedded in our culture, we are moving toward more sustainable products for our customers. Recycle-ready products with reduced carbon footprint are part of our research and development at every level.

Variable package sizes and emerging markets

Traditionally, motor oil packaging is made from bulky rigid plastic which takes up more shelf space, cargo space, requires additional packaging for shipping, and creates more waste in our landfills. We produce bag-in-box packaging for automotive fluids to accommodate the needs of our customers including, but not limited to:

- 1-liter pouches

- 5-liter bag-in-box

- 6-quart bag-in-box

- 3-gallon bag-in-box

- 6-gallon bag-in-box

This variety of packaging sizes allows retailers to carry a wider range of brands and product types to meet the needs of consumers. In addition to motor oil, bag-in-box packaging is used for antifreeze and automatic transmission fluids – with imminent expansion into other automotive products.

A global leader with local solutions

As a global leader in flexible packaging solutions, SIG recently surpassed a major production milestone of 60 million bag-in-box packages. We’ve integrated our packaging solutions with better dispensing technology and high-speed filling equipment. Our customers value our ability to engineer an entire solution from film, to fitment, to fill. That’s why we manufacture everywhere so we can serve you anywhere.

Benefits of our packaging

- Up to 99% production evacuation with minimal mess

- Lightweight, easy-to-open, and resealable

- Flexible sizing for the needs of our customers

- Secure, lightweight, ecommerce-ready pouches without the need for additional shipping material

- Better product-to-package ratio than traditional rigid formats like bottles, jars, and jugs

- Lightweight, strong, flexible packaging with many sustainability benefits

Fast-paced institutional filling and dispensing

We design our bag-in-box products with fast-paced institutional environments in mind. While working closely with end-users, we create easy-to-use products that work with nearly any dispensing system on the market.

- Sterile, closed-loop bag-and-fitment systems keep products safe from exposure

- Simple hoses and quick-connect systems for reliable, consistent dispensing

- Precise, controlled mixing for consistent quality

- Ability to fill and dispense low- or high-acid products from a single-fitment package

- Easy disconnection with less mess for dispenser cleaning protocols

Pouch packaging for motor oil

Increase your market appeal by offering motor oil in this highly-convenient packaging. Flexible spouted pouches are easy to reach into tight, awkward places inside engines, and are perfect for smaller amounts of motor oil for top-off or smaller engines, so consumers can purchase just what they need.

- Ship smarter with compact, flexible, ecommerce-ready pouches

- Visibility of volume in a package that dispenses with less mess

- Typically lower carbon footprint than heavy, rigid alternatives

- Better product-to-package ratio than rigid formats like bottles and jugs

Watch flexible packaging for automotive fluids in action

Our commitment to sustainability

In response to the changes in our climate and environment, we take seriously our commitment to reducing the impact of packaging on our earth. With a focus on sustainable production, waste prevention, and creating recyclable packaging, we partner with industry leaders to incorporate sustainability into our everyday business.

Our sustainable packaging solutions allow products to be shipped without any secondary packaging. Less packaging means less in our landfills. Better evacuation means less wasted product. We believe that this is good for business, good for people, and good for the environment.

We are focused on reducing our customers’ carbon footprint, reducing waste, and reducing the materials needed to make and ship our products. Far less packaging is involved in the flexible packaging we produce than rigid containers like bottles and jugs. Our development engineers are constantly finding ways to create packaging that enables the circular economy.

- luglio 01, 2022

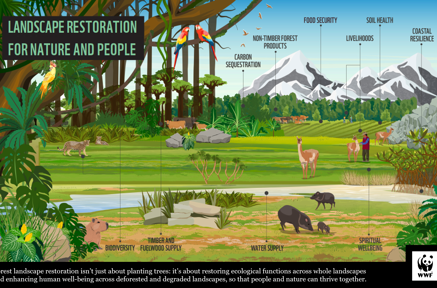

Beyond tree planting

The importance of psychological safety in fostering an open and inclusive work environment