Disclaimer

Images in the image gallery may only be used for editorial purposes in articles concerning the SIG Group (SIG), or articles referencing products from SIG, and may not be used in an offending or defamatory way. Images may not be altered in any way, except for cropping to fit into the layout of an article. No other rights than those restrictively provided herein are granted in respect of the images. By downloading an image, you accept these terms.

Images

66Topic

0.54 MB / JPG

Abdelghany Eladib

President & General Manager Middle East and Africa

0.36 MB / JPG

Angela Lu

President & General Manager Asia Pacific

0.30 MB / JPG

Ann-Kristin Erkens

Chief Financial Officer

1.59 MB / JPG

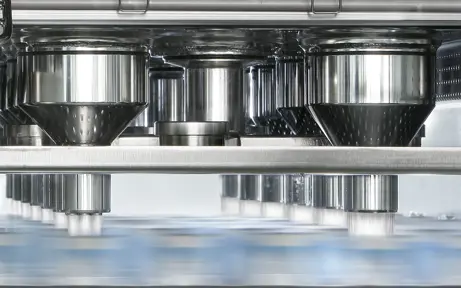

Aseptic zone

In the aseptic zone of the SIG filling machines, products that have previously undergone a UHT process are filled into the shaped, sealed and sterilized carton packs.

0.28 MB / JPG

Benefits of aseptic packaging

The first global launch of a long-life probiotic yogurt marks a major breakthrough for probiotic beverages and aseptic packaging. This game-changing development creates a new product category: probiotic beverages packed in aseptic carton packs and spouted pouches which are shelf-stable for prolonged storage periods without refrigeration.

0.33 MB / JPG

Christoph Wegener

Chief Markets Officer

0.96 MB / JPG

Close-up: filling juice

In the aseptic zone of the SIG filling machines, beverages that have previously undergone a UHT process are filled into the shaped, sealed and sterilized carton packs.

1.62 MB / JPG

Close-up: Filling liquid food product

SIG food filling machines are equipped with two separate dosing systems allowing food manufacturers to increase the scope of their aseptic food portfolio. Ingredients can be filled either in one single phase, which is the standard process, or in two separate phases.

1.75 MB / JPG

Close-up: filling SIG Drinksplus dairy product

SIG Drinksplus products like dairy products with aloe vera bits can be also processed and filled in aseptic carton packs on standard filling machines from SIG for liquid dairy products and non-carbonated soft drinks (NCSD). The bits can be up to six millimetres in length and width.

1.09 MB / JPG

Close-up: filling SIG Drinksplus juice product

SIG Drinksplus products like juice drinks with fruit or vegetable bits can also be processed and filled in aseptic carton packs on standard filling machines from SIG for liquid dairy products and non-carbonated soft drinks (NCSD). The bits can be up to six millimetres in length and width.

1.63 MB / JPG

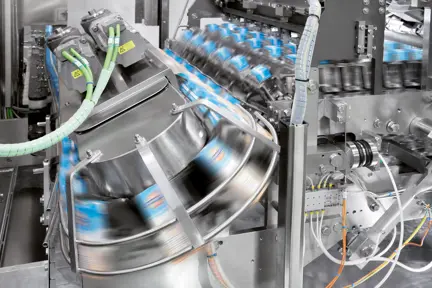

Close-up: running filling machine

In SIG filling machines, each carton pack is individually shaped and sealed at the bottom. The packs – still open at the top – are then guided to the aseptic zone of the filling machine via a mandrel wheel.

2.23 MB / JPG

Close-up: running filling machine into the downstream process

Once a carton pack has been filled with the product in SIG’s filling machines, the carton top is ultrasonically sealed above the fill level – still within the SIG filling machine. The carton packs are then fed fully automatically into the downstream process.

SIG Company Movie

Watch how we work in partnership with our customers to bring food products to consumers around the world in a safe, sustainable, and affordable way.

SIG 170 years anniversary

Let's embark on a fascinating journey through time as we tell the extraordinary story of SIG.

SIG DomeMini

SIG’s latest addition to the single-serve portfolio, redefines on-the-go packaging with its cutting-edge carton bottle design, setting a new standard for sustainability and convenience.

Toasting success with Winesmiths

Australian owned, grown, and produced Winesmiths crafts premium, vegan bag-in-box wine from South Australian grapes of a single vintage.

We’ve been a longtime partner with Winesmiths, and their choice to use our bag-in-box filling technology, featuring the widely known FlexTap, helps them bring their wine to environmentally-conscious consumers.

Growing in aseptic pouch

FirstWave’s mission is to enable entrepreneurs, growing brands, and innovative products into the aseptic food market at a 'right-sized' scale to minimize risk and to maximize access to high quality food processing technologies. We’ve been a longtime partner with FirstWave, from their start in aseptic pouches throughout their tremendous growth, and their choice to use our aseptic spouted pouch filling technology helps them bring high-quality products to consumers nationwide.

More videos