Have you ever tipped over a nearly-empty ketchup bottle, tapping the bottom to get the last bit out? Or maybe you’ve furiously tried to shake a shampoo bottle to get every drop? You know there’s still stuff in there, but the packaging poses some sort of limit.

Trying to empty a container of anything—from your favorite food items to personal care goods—can be incredibly challenging and highly wasteful. That’s why we designed the SIG DipStrip, an invention that helps empty packaging of everything that’s inside. The SIG DipStrip was designed with the post-mix syrup industry in mind, but the device works for nearly any product that requires a pump-out style of dispensing.

The SIG DipStrip is an evacuation device that goes inside a package. It’s a plastic strip made of channels designed to keep a bag from collapsing onto itself as it empties. It works kind of like a straw: as you empty a bag, the product is drawn through the SIG DipStrip’s open channels, toward the fitment, and then through the dispensing equipment.

Leave nothing behind

Decades ago, we developed the SIG DipStrip to combat waste associated with incomplete evacuation. After designing and testing prototypes, we took the SIG DipStrip to our Materials Science Lab and put it to the test. Our Materials Science Lab makes sure that the products we design perform as expected, so we asked them to design a series of experiments to see how effective the SIG DipStrip was at evacuating a bag-in-box package.

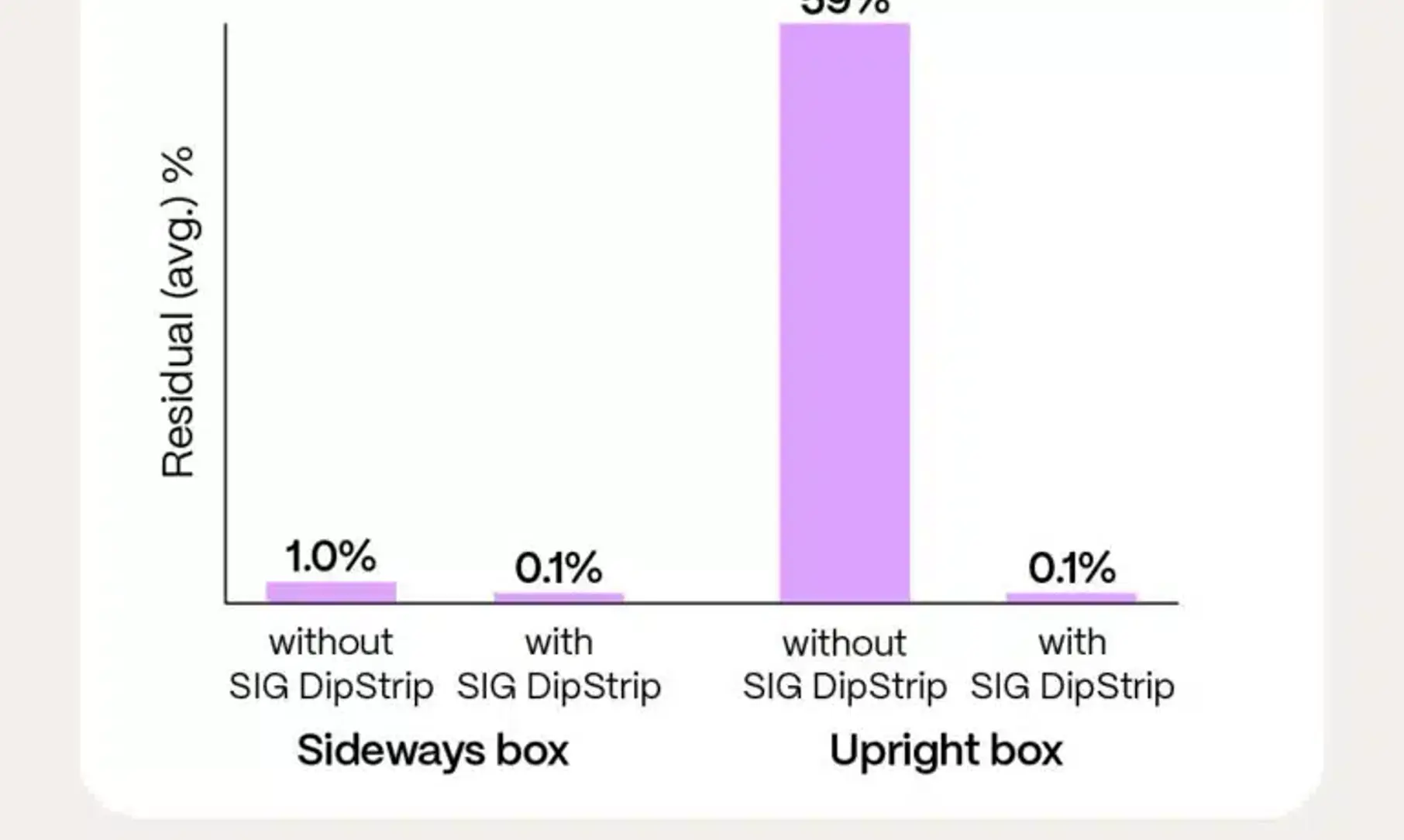

Our Materials Science Lab set up a comprehensive way to measure the evacuation percentage (how much product was left in a bag). The test was designed in a manner where we would fill two different packages with the same ingredient—one with a SIG DipStrip, and one without. Once dispensed to a point where no product was able to pump through the dispenser, we then measured how much product was left in each package. We also tested the SIG DipStrip in a few different positions to see if that affected how much product was left over.

What we found exceeded our expectations. The packages with a SIG DipStrip, on average, left 0.11% or less of product in their packaging (0.079% for packaging left sideways and 0.102% for packaging left upright), and every single set within each category that had a SIG DipStrip fell below the .3%—there were no outliers or failures within either group that had a SIG DipStrip. That’s great because all our testing packages met our target percentage.

But how does that compare with packaging without a SIG DipStrip?

Turns out, the SIG DipStrip made a big difference. On packages without a SIG DipStrip, those left sideways had about 0.985% of product left, which is above our percentage target. However, that number jumps when we tested with upright packaging: on average, packaging without a SIG DipStrip left 59.008% of product in the bag—that’s over half the product left inside!

A better evacuation solution

The SIG DipStrip is tried and tested. One of the biggest culprits contributing to waste is—quite literally—leaving usable products behind in a package. But the SIG DipStrip has the potential to make evacuation more efficient and save anywhere from a few ounces to over half the product in a package. These are savings you feel immediately within your supply chain and pass on to your consumers.

To explore your options and learn how to outfit your bag-in-box packaging with SIG DipStrip technology, contact us today!

Expert take: what makes baby food unique

Expert take: driving growth in functional drinks