Key features

Our small-size portfolio serves the classic single-serve sector. Provided the same base dimensions, we offer the industry's fastest change-over times for formats, volumes and design. With the ability to fill up to 24,000 packs per hour, our filling machines offer both high performance and low overall system costs. This speed, combined with low waste rates and unique flexibility definitely pays off. And thanks to their robust, well-engineered construction, the machines will continue to run reliably for many years.

12,000 pph

- Up to 9 volumes on one machine possible

- SIG Drinksplus and food options possible

- 4 tracks

- one trained operator can run the machine

24,000 pph

- Up to 9 volumes on one machine possible

- 6 tracks

- SIG Drinksplus and food options possible

- One trained operator can run the machine

SIG Drinksplus - Adding value to your product

Stand out in a competitive market by creating more healthy and premium products. Our complete end-to-end solution enables you to create innovative products and fill added-value products, such as premium fruit juices and drinkable milk snacks. Add real and natural food pieces – such as fruit, vegetables or cereal grains – to your beverages:

- chunky product ingredients up to 10%

- particulates can be up to 6mm

- fibers up to 1x15mm

- viscosity can be up to 3,500mPas.

New segments - low investment

Use standard filling machines to expand your product range, achieve higher margins, or enter and test new market segments – without a major investment. For SIG SmallBloc, we also offer the Food Option solution: Food Option filling machines are based on our standard filling technology and include minor technical adjustments that allow you to fill a whole host of additional food products:

- Chunky product ingredients up to 15%

- Particulates up to 6mm

- Fibers 1x15mm

- Viscosity up to 3,500mPas

SIG CompactBloc 12 Aseptic Food

For SIG CompactBloc, we offer a special food filling machine which makes it possible to fill products with larger particulates and particulate content as well as higher viscosity. This makes it the perfect choice for soups, sauces and desserts.

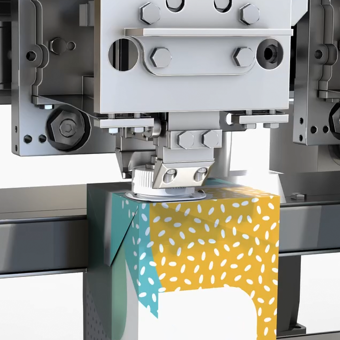

SIG Applicators

- SIG Bloc Cap Applicator: The post-application of the spouts with an applicator makes it possible to fill different formats on one line and increase the aseptic safety.

- SIG Bloc/Fit Cap Applicator: For filling machines, which can fill two different formats, the applicator also forms the package after the filling process and gives it the final shape.

Formats and matching filling machines

SIG Small 12 Aseptic and SIG Small 24 Aseptic

SIG MiniBloc 12 Aseptic and SIG MiniBloc 24 Aseptic

SIG XSlimBloc 12 Aseptic and SIG XSlimBloc 24 Aseptic

SIG CompactBloc 12 Aseptic, SIG CompactBloc 12 Aseptic Food

Small-size formats