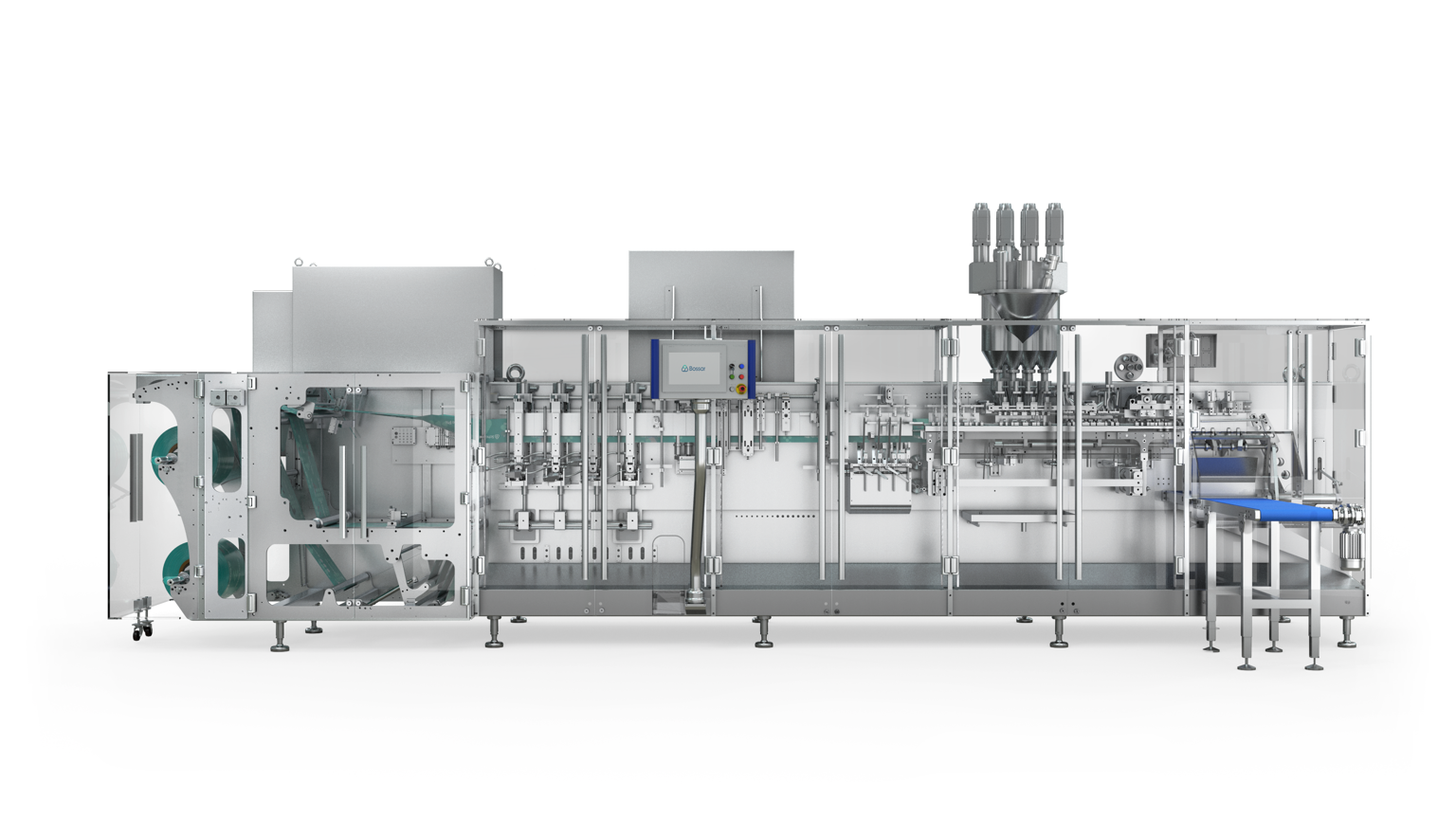

Efficient medium-sized sachet packaging

Medium packs, maximum efficiency

The SIG Bossar 300 Sachet 3.2 is designed to efficiently package medium-sized sachets, meeting the rigorous standards of a wide range of industries. Its full servo motion technology ensures precise operations, while the oil-free design reduces maintenance efforts. With a production capacity of up to 360 sachets per minute, it enhances productivity for medium to large-scale manufacturing lines.

The SIG Bossar 300 Sachet 3.2 offers versatility by accommodating various sachet formats, including flat 3-side seal, flat 4-side seal, twin sachets, and string sachets. Its optimized design allows for swift format changeovers, facilitating seamless transitions between different products. The hygienic construction, with isolated internal drives and servo motors, ensures compliance with industry cleanliness standards, safeguarding product integrity.

Compatible pouch formats

Offer your products in simple, pouch packaging. Our innovative solutions are engineered to protect your products from fill through final use.

- Multiple size and shapes available to fit any brand

- Zipper and tear-top styles that let your consumers have quick access to your products

- Multi-use packaging that’s re-closeable and portable

Equipment specifications

Key features

-

Low Maintenance: Oil-free operation reduces maintenance time and costs.

-

Flexible Format Changes: Supports multiple sachet formats with optimized changeover times.

-

High-Speed Production: Capable of producing up to 360 sachets per minute.

-

Hygienic Design: Isolated internal drives ensure compliance with cleanliness standards.

Product benefits

Oil-free operation minimizes downtime and maintenance costs

Supports various sachet types for diverse product needs

optimized design allows for rapid format transitions

Increases output with speeds up to 360 sachets per minute

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Retort

Fills, seals, and heats products in pack to high temperatures until the container is heated to the center, rendering the product commercially sterile.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| (mL) | Max pouch width (mm) | (Pouches per Minute) |

| 50.0 | 80 | 300 |