Introducing...

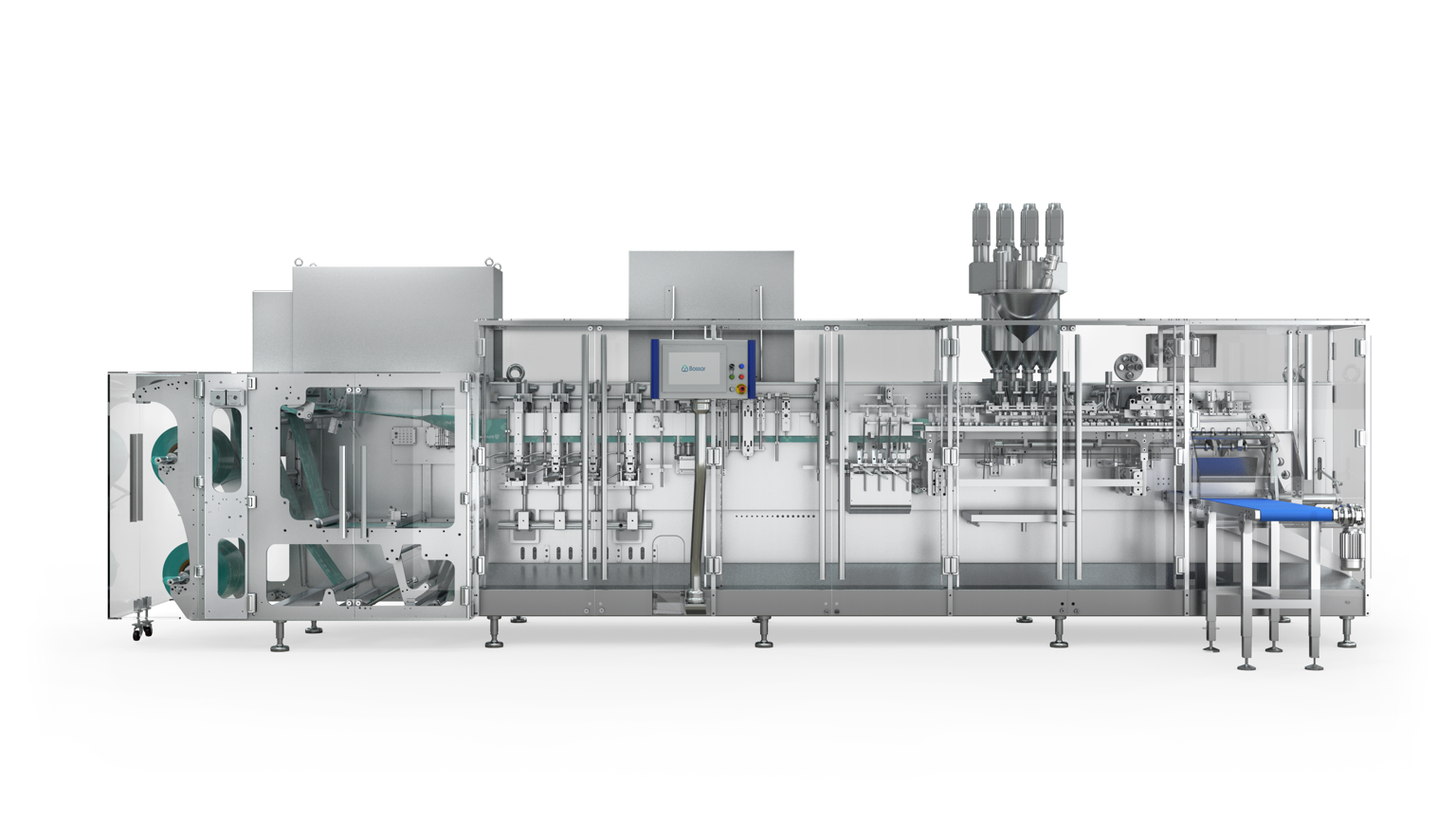

The SIG Bossar Sachet Series

The SIG Bossar Sachet Series offers a comprehensive range of Horizontal Form-Fill-Seal (HFFS) machines engineered to meet the diverse packaging needs of various industries, including food, pharmaceuticals, cosmetics, and chemicals. These machines are designed to produce high-quality sachets with precision and efficiency, ensuring product integrity and consumer satisfaction.

The SIG Bossar Sachet Series includes the SIG Bossar 200 Sachet 1.4, SIG Bossar 300 Sachet 2.8, SIG Bossar 300 Sachet 3.2, and SIG Bossar 300 Sachet 3.8. Each model is specifically tailored to accommodate specific production requirements, offering flexibility in sachet sizes and filling capacities. With features like full servo motion control, hygienic design, and user-friendly interfaces, these machines ensure optimal performance and ease of operation.

Compatible pouch formats

Offer your products in simple, pouch packaging. Our innovative solutions are engineered to protect your products from fill through final use.

- Multiple size and shapes available to fit any brand

- Zipper and tear-top styles that let your consumers have quick access to your products

- Multi-use packaging that’s re-closeable and portable

Equipment specifications

Key features

-

Modular Design: Allows for customized configurations to meet specific production needs.

-

High-Speed Production: Capable of producing up to 360 sachets per minute, enhancing productivity.

-

Hygienic Construction: Designed with sanitary features suitable for pharmaceutical and cosmetic industries.

-

Full Servo Motion Control: Ensures precise operations and reduces maintenance requirements.

-

User-Friendly Interface: Intuitive touch screens for easy operation and quick adjustments.

Product benefits

Suitable for packaging liquids, solids, and wet wipes, catering to food, pharma, and cosmetic sectors.

Oil-free and grease-free operations minimize maintenance time and costs.

Most adjustments can be made via the touch screen, eliminating the need for manual mechanical interventions.

Accommodates various production scales, from small batches to large-scale manufacturing.

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Retort

Fills, seals, and heats products in pack to high temperatures until the container is heated to the center, rendering the product commercially sterile.