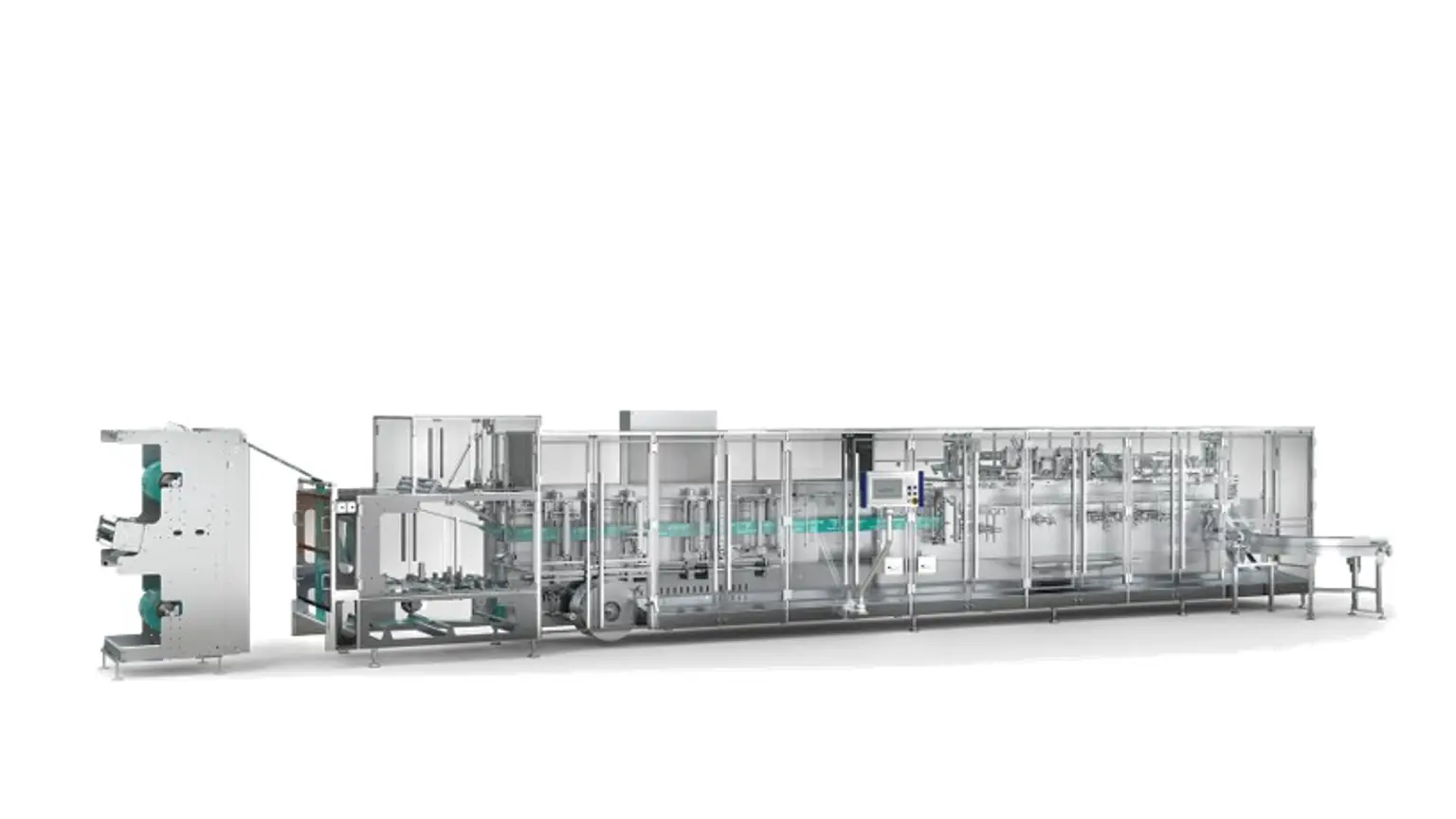

Big formats, quick changeovers, and reliable performance

The SIG Bossar Carousel System (BCS) is designed to handle large pouch formats with unmatched efficiency and precision. Engineered for industries requiring substantial output, such as food, pet food, and household goods, the BCS offers advanced flexibility with fast format changeovers to minimize downtime. Its robust design ensures operational longevity and adaptability to a wide range of products.

The SIG Bossar Carousel System stands out with its ability to produce large pouches while maintaining high operational efficiency. Designed with ease of use and scalability in mind, it accommodates multiple pouch styles: flat, stand-up, with fitments, or without.

Its quick changeover functionality ensures adaptability to evolving production demands, making it an ideal choice for manufacturers looking to optimize performance without sacrificing flexibility. Key benefits include:

-

Seamless production of big-format pouches

-

Customizable configurations to suit specific product needs

-

Reduced downtime through rapid format changes

Whether you are in food, personal care, or industrial markets, the SIG Bossar Carousel System delivers reliability, precision, and speed.

Compatible pouch formats

Offer your products in simple, pouch packaging. Our innovative solutions are engineered to protect your products from fill through final use.

- Multiple size and shapes available to fit any brand

- Zipper and tear-top styles that let your consumers have quick access to your products

- Multi-use packaging that’s re-closeable and portable

Equipment specifications

Key features

-

Big Format Capability: Designed for large pouches and big-volume products.

-

Quick Changeover: Optimized for rapid transitions between pouch formats.

-

High-Speed Production: Achieves filling speeds of up to 400 pouches per minute.

-

Customizable Options: Supports fitments, zippers, and spouts for versatile pouch designs.

-

Operator-Friendly Design: Easy-to-use interface for streamlined operation and maintenance.

Product benefits

Modular, oil-free design reduces upkeep and downtime.

Supports large pouches with optional spouts and zippers.

Achieves speeds of up to 400 pouches per minute.

Transition between formats efficiently for maximum productivity.

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Retort

Fills, seals, and heats products in pack to high temperatures until the container is heated to the center, rendering the product commercially sterile.