Medium-format versitility

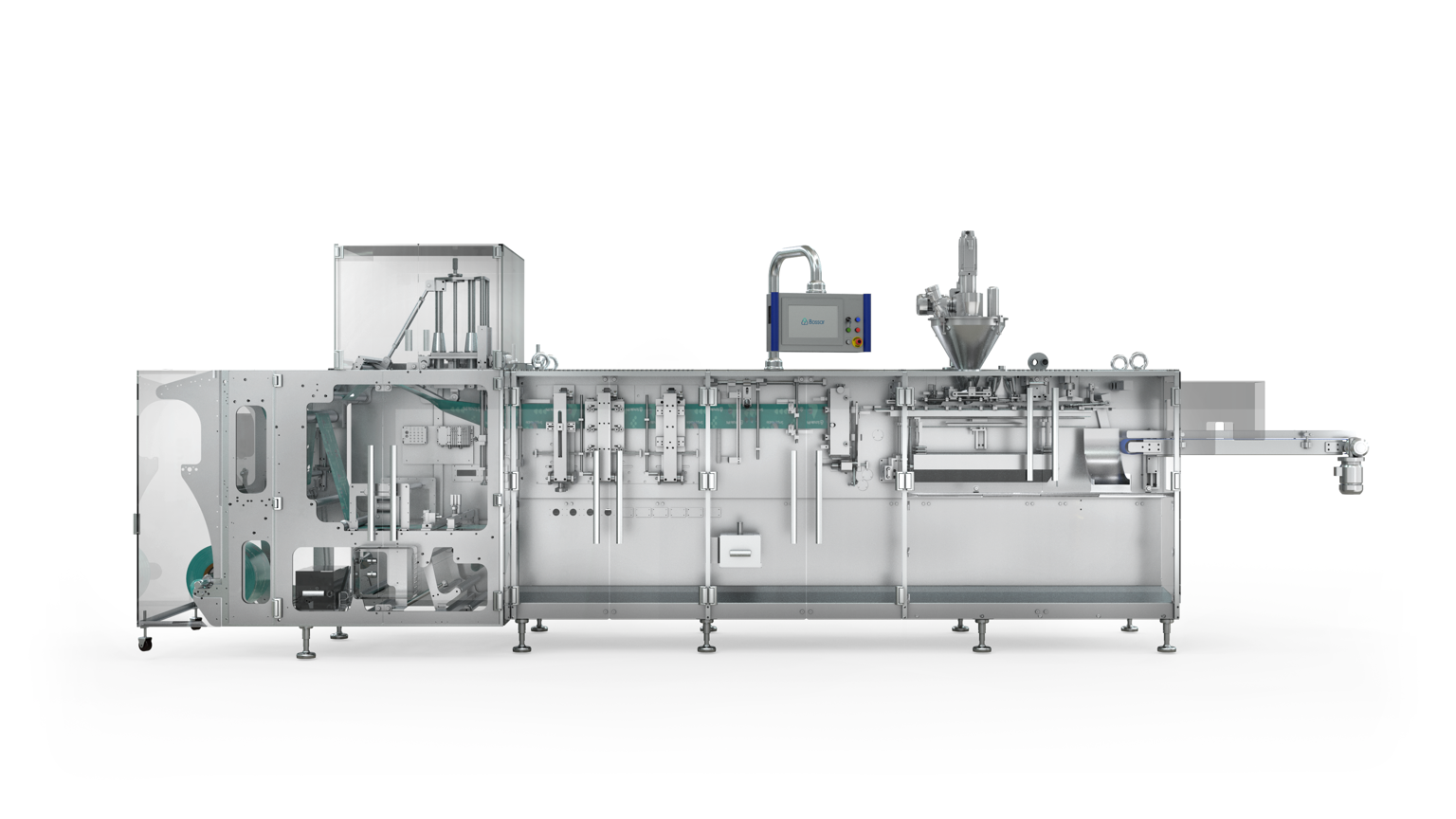

The SIG Bossar Basic 1.6 is a adaptable Horizontal Form-Fill-Seal (HFFS) machine designed for medium-sized pouch production. Built for flexibility and performance, it supports a wide range of products, including powders, granules, and solid goods.

Able to handle pouch sizes up to 1 liter and produce up to 180 pouches per minute, the Basic 1.6 offers unmatched efficiency for industries like food, personal care, and household products. Its compatibility with various dosing systems ensures precise filling while maintaining product integrity.

The SIG Bossar Basic 1.6 provides a modular and versatile platform for manufacturers requiring flexibility in pouch design and dosing. It seamlessly accommodates various pouch types, such as stand-up pouches with zippers or fitments, and flat 3-side and 4-side sealed pouches.

Key highlights include:

-

Adaptable dosing systems: Supports powder and solid dosing for multi-product capability.

-

Flexible production outputs: Handles a variety of pouch sizes, up to 1L, with quick changeovers.

-

High operational efficiency: Optimized to produce up to 180 pouches per minute without compromising accuracy.

Perfect for businesses looking to scale medium-format pouch production while maintaining flexibility and precision.

Compatible pouch formats

Offer your products in simple, pouch packaging. Our innovative solutions are engineered to protect your products from fill through final use.

- Multiple size and shapes available to fit any brand

- Zipper and tear-top styles that let your consumers have quick access to your products

- Multi-use packaging that’s re-closeable and portable

Equipment specifications

Key features

- Flexible Pouch Formats: Produces stand-up, flat, and zipper pouches up to 1L capacity.

- High-Speed Output: Achieves production speeds of up to 180 pouches per minute.

- Dosing Versatility: Supports powder and solid filling systems.

- User-Friendly Design: Intuitive controls for quick adjustments and seamless operation.

- Modular Efficiency: Optimized for quick format changeovers, reducing downtime.

Product benefits

Handles stand-up, flat, and zipper pouches for diverse product applications.

Supports powders and solids with precise accuracy.

Intuitive interface for seamless production adjustments.

Produces up to 180 pouches per minute with optimized performance.

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Retort

Fills, seals, and heats products in pack to high temperatures until the container is heated to the center, rendering the product commercially sterile.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| (mL) | Max pouch width (mm) | (Pouches per Minute) |

| 80.0 | 80 | 180 |

| 800.0 | 160 | 90 |