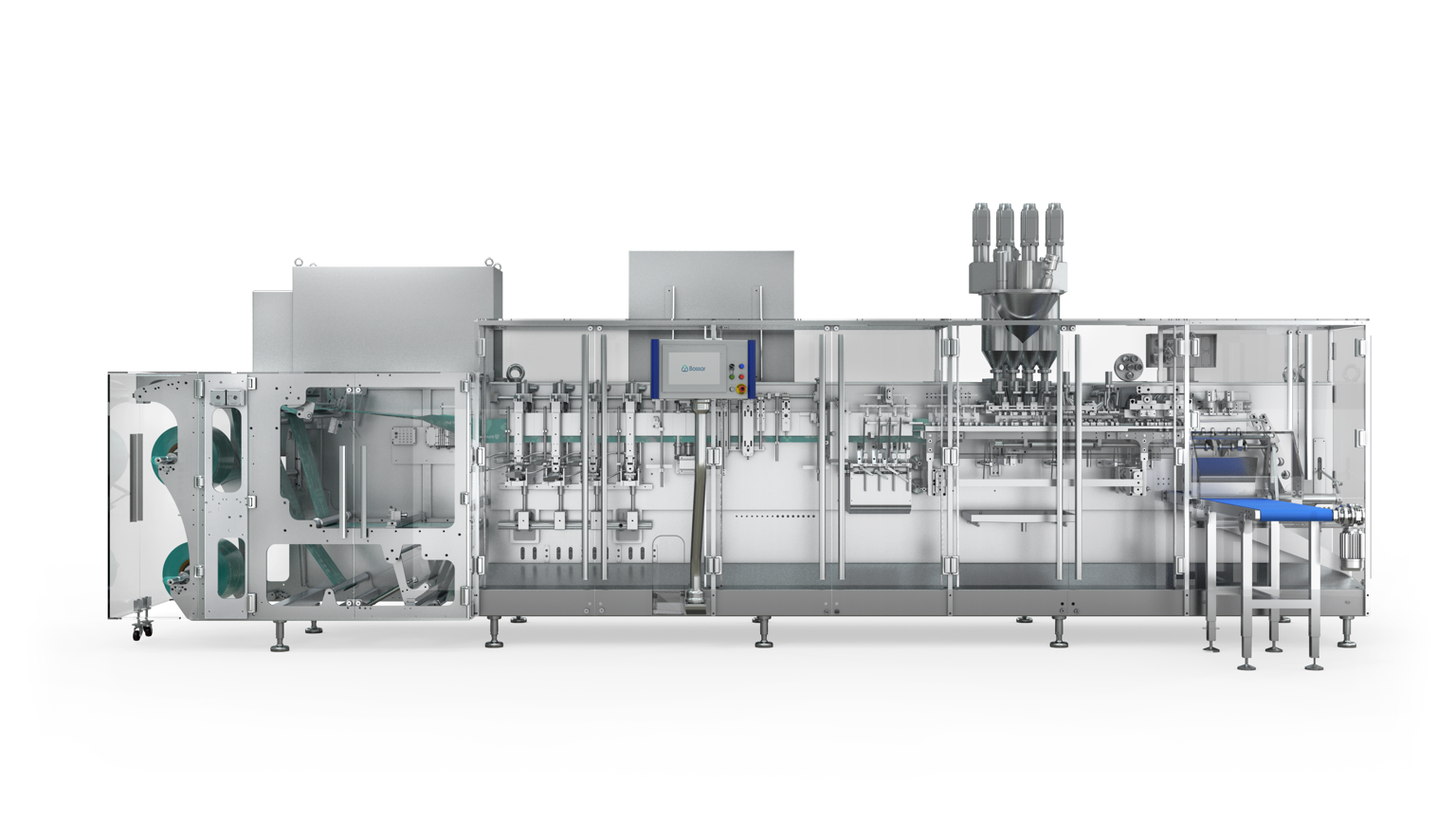

Advanced sachet packaging

The SIG Bossar 200 Sachet 1.4 is engineered to deliver high-performance sachet packaging for various industries. Its compact footprint and advanced technology make it an ideal choice for businesses seeking efficiency and reliability in their packaging processes.

Designed to handle a range of sachet sizes, the SIG Bossar 200 Sachet 1.4 offers flexibility for packaging small to medium-sized products. Its intuitive controls and robust construction ensure consistent performance, meeting the demands of modern production.

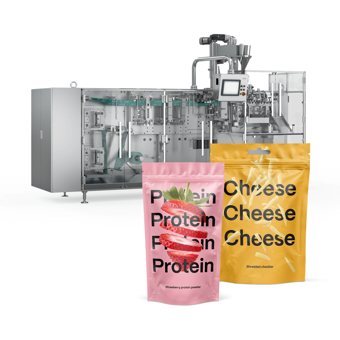

Compatible pouch formats

Offer your products in simple, pouch packaging. Our innovative solutions are engineered to protect your products from fill through final use.

- Multiple size and shapes available to fit any brand

- Zipper and tear-top styles that let your consumers have quick access to your products

- Multi-use packaging that’s re-closeable and portable

Equipment specifications

Key features

- Compact Design: Fits seamlessly into limited production spaces.

- Versatile Sachet Sizes: Accommodates a range of product volumes.

- User-Friendly Interface: Simplifies operation and reduces training time.

- High Efficiency: Optimizes production speed without compromising quality.

Product benefits

ideal for facilities with limited floor space

Supports various sachet dimensions for diverse products

Intuitive controls enhance operational efficiency

Increases output while maintaining product quality

Known process applications

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Retort

Fills, seals, and heats products in pack to high temperatures until the container is heated to the center, rendering the product commercially sterile.

Filling speeds

| Package Size | Filling Speed | |

|---|---|---|

| (mL) | Max pouch width (mm) | (Pouches per Minute) |

| 50.0 | 70 | 220 |

| 320.0 | 140 | 110 |