A new era of sustainability

In the final part of our Unpacking Sustainability series, we recount the many ways food and beverage manufacturers can embrace a greener, more sustainable business model.

Between globally recognised environmental certifications, alu-free aseptic carton packs and a whole lot more, what does the green shift look like for food and beverage manufacturers? Find out in our series recap.

The sustainable shift

Why are consumers more invested in sustainability, and how is this impacting their purchasing decisions? The factors and trends shaping how the world lives and consumes may vary, but the common consensus is that industries should take the lead to create real change. And, although food and beverage manufacturers are making inroads with their sustainability initiatives, there is plenty more to be done.

Behind the labels

The food and beverage industry faces a gap between meeting the demands of more conscious consumers and ensuring they have all the information they need to make a purchase. Certifications can play a big role in fostering trust among consumers while ensuring manufacturers remain accountable. What are the most relevant certifications within food and beverage and what do they entail?

Cracking the aluminium challenge

Why do we use aluminium in aseptic carton packs, and how can we create greener alternatives? To make the industry’s first-ever alu-free aseptic structure required innovation across the value chain – from sourcing the right materials, to ensuring food safety and shelf stability. For SIG, it also meant asking what else could be done to reduce our reliance on aluminium.

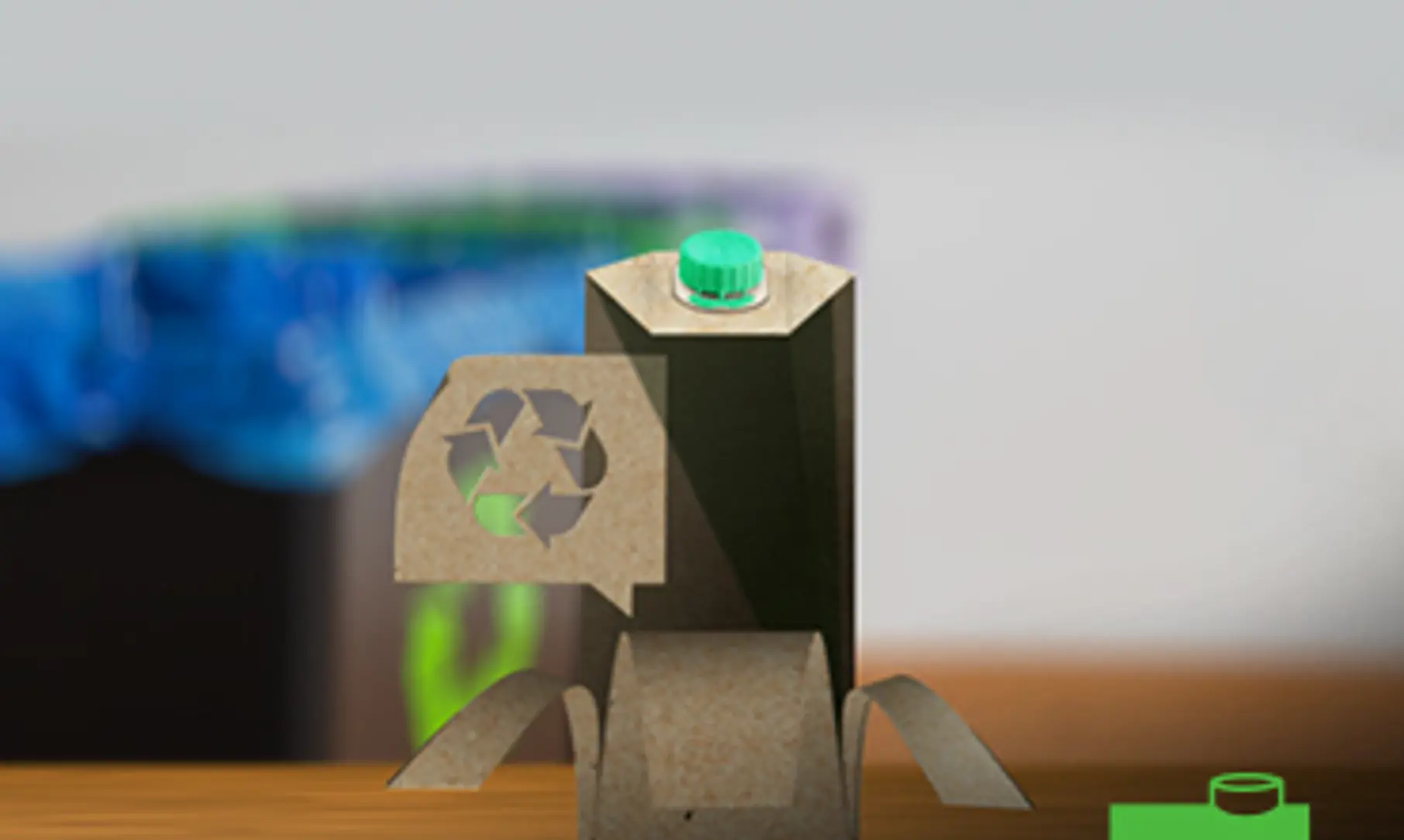

Towards circular packaging

The world has already welcomed the first aseptic pack linked to 100% plant-based materials. But, given the complex dynamics behind circular packaging, how are plant-based packs actually made and when can manufacturers label a carton as plant-based? Is it feasible to imagine the food and beverage industry shifting to 100% bio-based packaging, or should we turn our focus elsewhere?

Making every piece count

With only 14% of all the plastic packaging the world consumes being collected for recycling, the onus is on manufacturers to step up and lead the fight against plastic waste. What can be done to keep plastic out of our oceans and off our lands? Is it enough to switch to alternative forms of packaging or is there more to consider?

What comes next

With so many things to focus on when striving for a more – if not fully – sustainable business model, the process can appear daunting. Indeed, as well as everything covered in our series, there are many more things manufacturers should consider as part of their green journey, not least of which is recycling. Because here, the challenge doesn’t just lie in making carton packs fully recyclable – it lies in making sure this knowledge is communicated to consumers.

At SIG, we are serious about sustainability, which is why we have the solutions, skills and drive to help you achieve your goals faster. Not only do we know what goes into every one of our solutions, where every material was sourced, and what our impact is on the environment. We also know how to apply these same principles to your business. With us by your side, we can support the transformation of your entire supply chain: from making more informed decisions about your sustainability practises, to switching to faster, more efficient filling machines.

For more stories like this delivered straight to your inbox, subscribe to the SIGnals Update, our exclusive bi-weekly newsletter.

- september 01, 2021