How are cartons reborn?

Recycling is a way of life today but what is the end result of recycling? Let’s turn our Recycling Spotlight on how cartons find a new persona in their second life.

Consumers today often opt for recycled products when shopping and also diligently do their bit in disposing food and beverage cartons correctly. But how do these packs find a new life? What does their second innings look like?

We have already had a behind-the-scenes look at the entire recycling process of aseptic cartons. Now, let’s find out the different ways in which cartons are repurposed into brand new products.

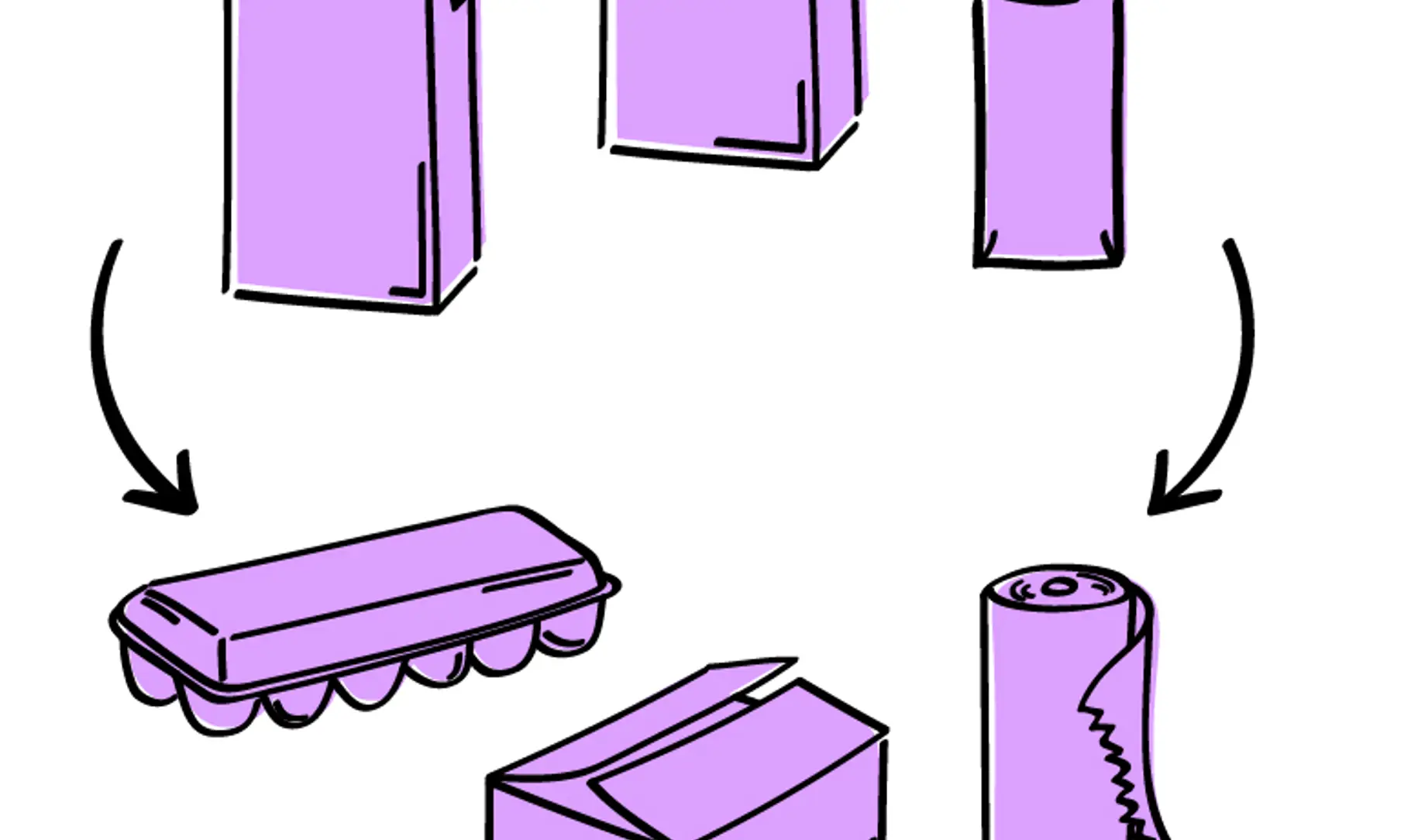

The circle of paper

Aseptic cartons are predominantly made up of liquid paperboard, which is a high-value material in the recycling value chain. The paper fibres retain their strength even after they are extracted from used cartons, making these ideal raw materials for a variety of paper-based products. From rolls of kitchen towels and notebooks to egg cartons and packaging boxes – cartons find a new life in a multitude of everyday products.

The value of polyAI

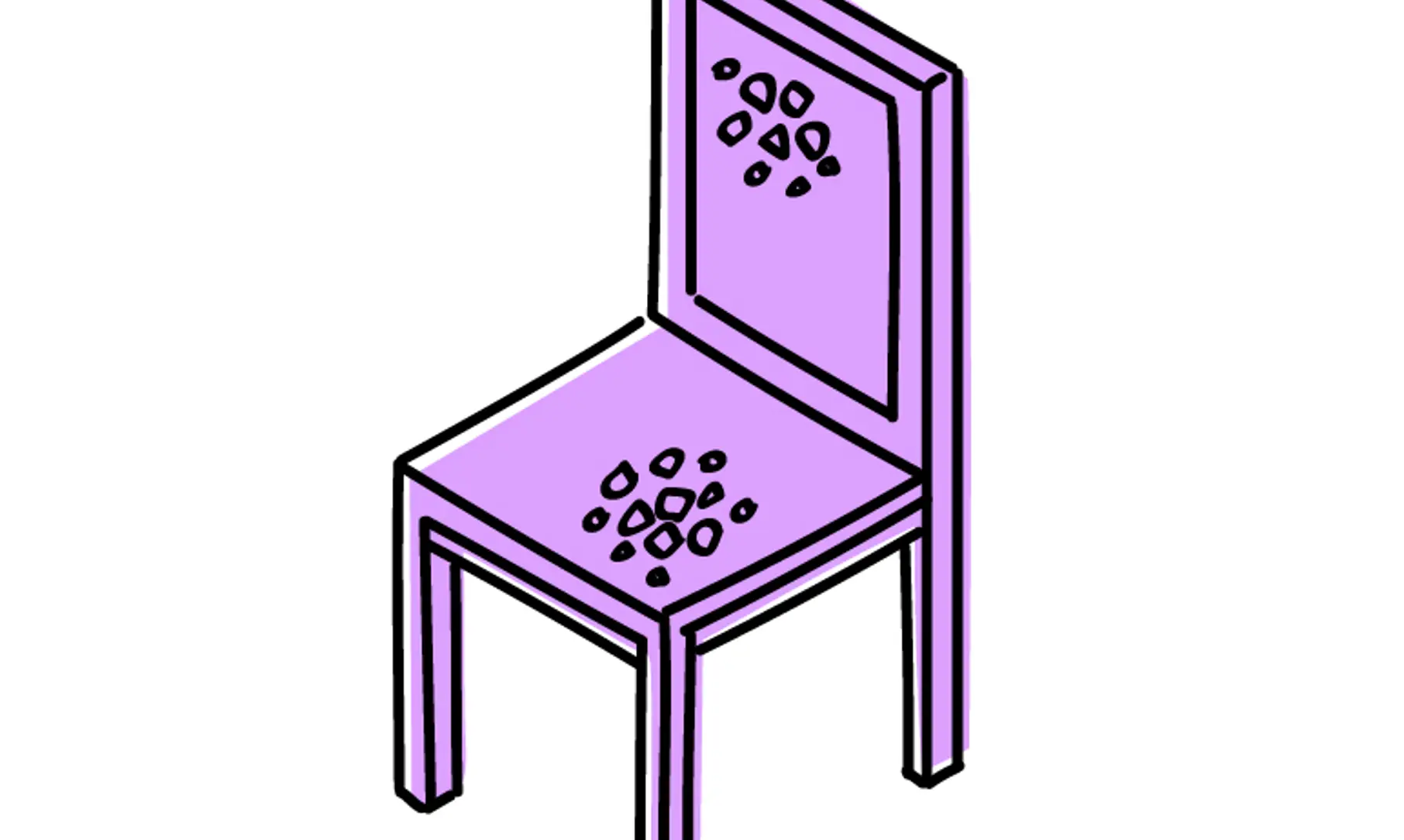

The shelf stability of aseptic cartons is usually aided by thin layers of polyethylene and aluminium. After the paper fibres are extracted from the used cartons, the residual material is referred to as polyaluminium or PolyAI. This has been traditionally considered a difficult-to-recycle component and was reduced to being used as fuel in cement industries. But that has changed in the recent years. Today, there are multiple organisations who specialise in creating high-quality raw materials from PolyAl, which are then used by innovative manufacturers for a variety of products.

PolyAl has emerged to be a versatile material with significant potential of being used in high-value products. The material even made a debut at the Milan Design Week 2022 as a 3D-printed furniture line. Closer home, PolyAl is being used to make a wide range of everyday items such as pens, household items, decorative pieces, and even automotive parts.

The strength of mixed materials

The multiple layers in an aseptic carton lend the structure its strength and rigidity. And with recycling innovation, that strength can be increased manifold – enough to be used as construction materials. Companies, like saveBOARD, are turning aseptic packs into high-performance building materials in Oceania. Elsewhere, the material is being used differently, ranging from roofing sheets to school furniture.

Take the case of the Eco-Canteen made almost entirely from used beverage cartons in Thailand, park benches in India, or upcycled designer furniture in Philippines.

SIG taking it further

At SIG, we are always striving for better – better for the environment and the coming generations. In line with our commitment, we played a pivotal role in developing an advanced level of recycling that turns PolyAI into marketable raw materials at the first of its kind recycling plant, Palurec GmbH, in Germany. And now we are pioneering this technology in Brazil in our newest recycling plant, expected to be operational in 2024.

Sustainable innovation is the way forward for our planet. And the role of effective and efficient recycling cannot be downplayed as industries strive to be more circular. If you have missed out on any of the topics in this series, catch up on innovative recycling practises and processes in the final recap post of Recycling Spotlight. Subscribe to our exclusive bi-weekly newsletter for this post and more.

- 4月 06, 2023